Selecting the right motor type is crucial for the success of any motion control project. Sinbad Motor offers a comprehensive range of motor types to suit various motion characteristics, ensuring that every drive system is perfectly matched to its application.

1. AC Series Wound Motor

Your Reliable Ally: The AC Series Wound Motor is the backbone of countless household appliances, offering unwavering performance day after day.

- Why It Stands Out: Known for its durability and cost-effectiveness, this motor is the go-to choice for manufacturers seeking a balance of value and reliability.

- Application Example: Ideal for home appliances such as washing machines and fans, which demand reliable, extended use with minimal servicing.

2. Permanent Magnet DC Brushed Motor

The Powerhouse: With its impressive torque and quick response, the Permanent Magnet DC Brushed Motor is the perfect fit for power tools that demand precision and control.

- What You Get: These motors are engineered for high performance and are designed to handle the rigors of professional use, ensuring that your tools are always ready when you are.

- Choose the Best: Sinbad Motor's DC Brushed Motors are crafted with high-grade materials for longevity and are backed by a commitment to excellence.

- Application Example: A staple in power tools like drills and grinders, where rapid response is crucial for effective operation.

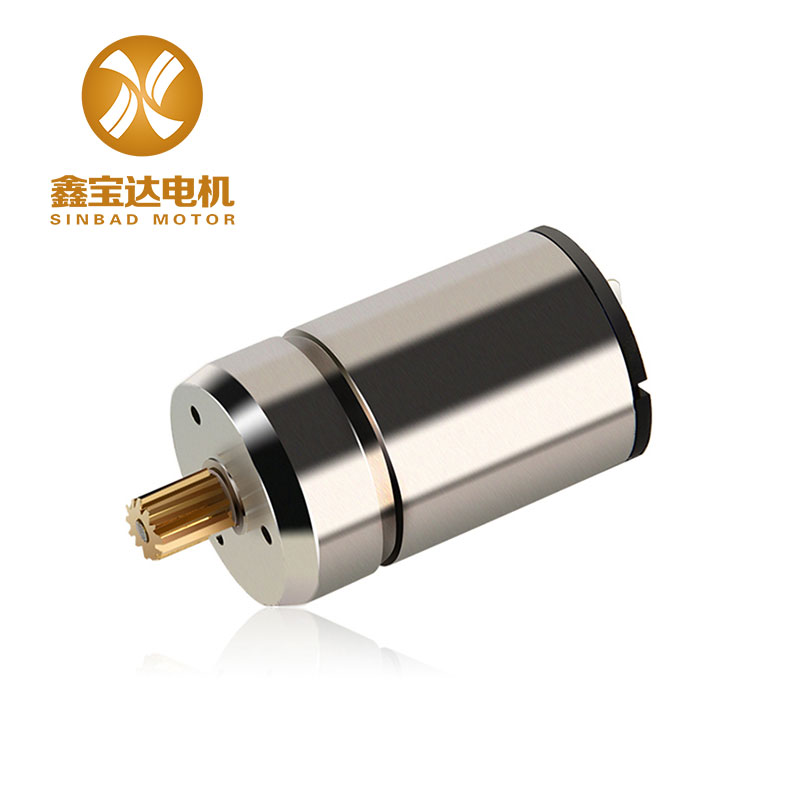

3. Brushless DC Motor (BLDC)

The Future of Motion: The BLDC Motor is the driving force behind the next generation of electric vehicles and advanced bicycle systems, providing a new level of efficiency and control.

- Innovative Design: These motors are at the cutting edge of motor technology, offering smooth and responsive power delivery that enhances the user experience.

- Leading the Way: Sinbad Motor's BLDC Motors are designed to meet the evolving needs of the transportation industry, with a focus on sustainability and performance.

- Application Example: Preferred in electric vehicles and bicycles for their ability to provide a smooth, power-efficient driving experience.

Selecting the Appropriate Motor Type Based on Motion Characteristics

☀For continuous operations with minimal gear shifting, the AC Series Wound Motor is the preferred choice.

- This motor type offers a steady and reliable performance, making it ideal for applications that require a constant and unwavering power source.

☀For intermittent dynamic applications, Brushed DC Motors or Brushless DC Motors are considered ideal.

- These motors provide the necessary flexibility and control for applications that involve variable speeds and frequent starts and stops.

☀For low-speed, high-torque applications, the Gearbox Motor, which combines either an AC or DC motor with a gearbox, is a must.

- This configuration allows for achieving the desired torque and speed ratios, making it perfect for machinery and equipment that demand high force at lower speeds.

☀For applications requiring infinite speed adjustment, the Brushless DC Motor stands out as the best option.

- With its electronic commutation, this motor type offers a wide range of speed control without the need for physical brushes, enhancing efficiency and reliability.

☀For applications that demand precise positioning, Stepper Motors are the go-to choice.

- These motors provide a high degree of accuracy and are capable of complex motion control, making them suitable for systems where exact positioning is critical.

Determining Technical Specifications and Size After Motor Type Selection

Once the motor type is selected, it is crucial to determine the technical specifications of the motor, including its power, torque, and speed.

★These parameters are fundamental in ensuring that the motor can meet the performance requirements of the application.

The size and dimensions of the motor must also be established, considering how it will be integrated and secured within the system.

★The physical footprint and mounting arrangements are key factors in the design and installation process.

When selecting the size and robustness of the motor, the industrial environment in which it will operate must be taken into account.

★Different environments, such as those prone to explosions, dampness, corrosive substances, or extreme temperatures, require specific designs to ensure motor safety and longevity.

For harsh environments, it may be necessary to equip the motor with additional protective casings that are waterproof, dustproof, and shockproof.

Considering Local Energy Regulations When Determining Motor Type

Finally, it is essential to consider the energy regulations of the region or country where the motor will be used.

★Motors with higher energy efficiency ratings not only contribute to environmental sustainability but also offer cost savings in the long run by reducing energy consumption.

Editor : Carina

Post time: Apr-10-2024