Composition

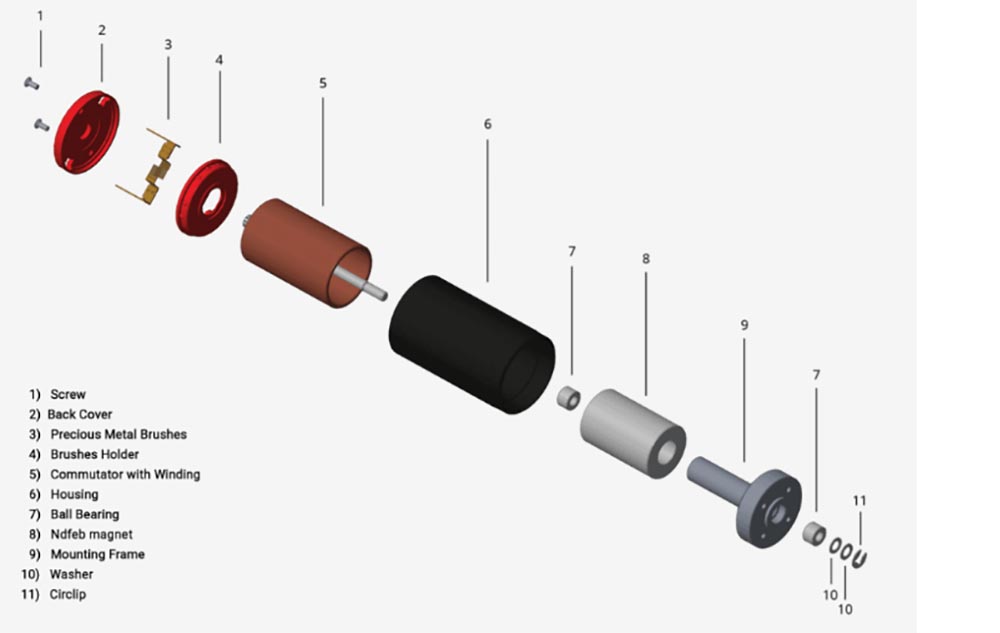

1. Permanent magnet DC motor:

It consists of stator poles, rotors, brushes, casings, etc.

The stator poles are made of permanent magnets (permanent magnet steel), made of ferrite, alnico, neodymium iron boron and other materials. According to its structural form, it can be divided into several types such as cylindrical type and tile type.

The rotor is generally made of laminated silicon steel sheets, and the enameled wire is wound between the two slots of the rotor core (there are three windings in three slots), and the joints are respectively welded on the metal sheets of the commutator.

The brush is a conductive part that connects the power supply and the rotor winding, and has two properties of conductivity and wear resistance. The brushes of permanent magnet motors use single-sex metal sheets or metal graphite brushes, and electrochemical graphite brushes.

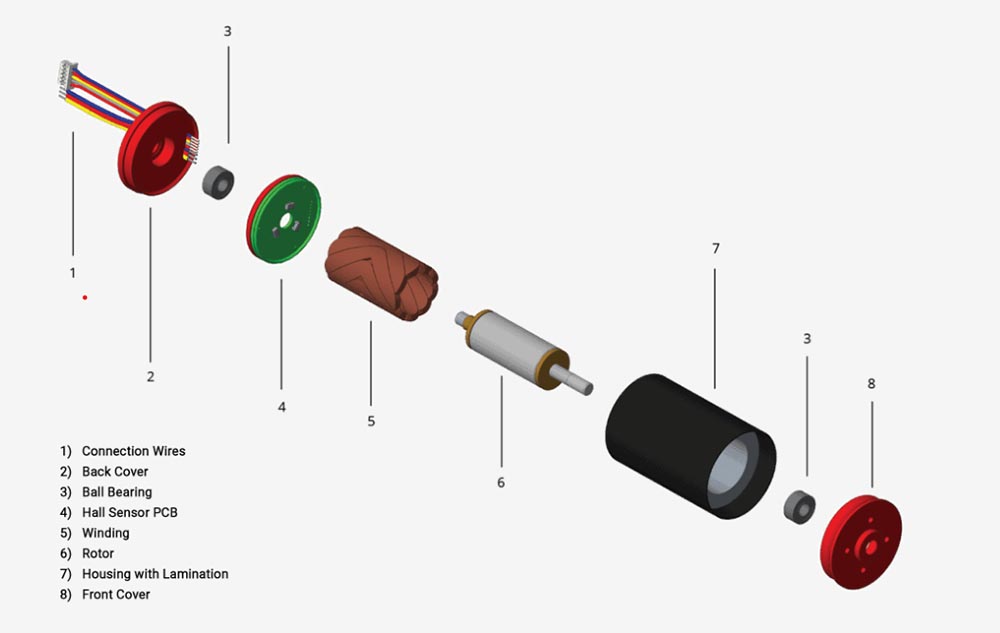

2. Brushless DC motor:

It is composed of permanent magnet rotor, multi-pole winding stator, position sensor and so on. The brushless DC motor is characterized by being brushless, and uses semiconductor switching devices (such as Hall elements) to realize electronic commutation, that is, electronic switching devices are used to replace traditional contact commutators and brushes. It has the advantages of high reliability, no commutation spark, and low mechanical noise.

The position sensor commutates the current of the stator winding in a certain order according to the change of the rotor position (that is, detects the position of the rotor magnetic pole relative to the stator winding, and generates a position sensing signal at the determined position, which is processed by the signal conversion circuit and then removed. Control the power switch circuit, and switch the winding current according to a certain logic relationship).

2. Brushless DC motor:

It is composed of permanent magnet rotor, multi-pole winding stator, position sensor and so on. The brushless DC motor is characterized by being brushless, and uses semiconductor switching devices (such as Hall elements) to realize electronic commutation, that is, electronic switching devices are used to replace traditional contact commutators and brushes. It has the advantages of high reliability, no commutation spark, and low mechanical noise.

The position sensor commutates the current of the stator winding in a certain order according to the change of the rotor position (that is, detects the position of the rotor magnetic pole relative to the stator winding, and generates a position sensing signal at the determined position, which is processed by the signal conversion circuit and then removed. Control the power switch circuit, and switch the winding current according to a certain logic relationship).

3. High speed permanent magnet brushless motor:

It is composed of stator core, magnetic steel rotor, sun gear, deceleration clutch, hub shell and so on. A Hall sensor can be mounted on the motor cover for speed measurement.

Comparison of brushed motors and brushless motors

The difference in the electrification principle between a brushed motor and a brushless motor: A brushed motor is mechanically commutated by a carbon brush and a commutator. A brushless motor is electronically commutated by a controller based on an induction signal

The power supply principle of brushed motor and brushless motor is different, and its internal structure is also different. For hub motors, the output mode of the motor torque (whether it is decelerated by the gear reduction mechanism) is different, and its mechanical structure is also different.

coreless brushed dc motor

coreless brushless dc motor

Post time: Jun-03-2019