Geared stepper motors are a popular type of speed reducer, with the 12V variant being especially common. This discussion will provide an in-depth look at stepper motors, reducers, and stepper gear motors, including their construction. Stepper motors are a class of sensor motor that functions by transforming direct current into a polyphase, sequentially controlled current using an electronic circuit. This process enables the stepper motor to operate. The driver, serving as a sequential controller for multiple phases, supplies a timed power source to the stepper motor.

Stepper motors are open-loop control motors that convert electrical pulse signals into angular or linear displacements. As a key actuator in modern digital control systems, they are valued for their accuracy. The motor's speed and the final position are determined by the frequency and number of pulses in the signal, remaining unaffected by changes in the load. Once the stepper driver receives a pulse signal, it prompts the stepper motor to rotate through a set angle, referred to as the "step angle," moving in precise, incremental steps.

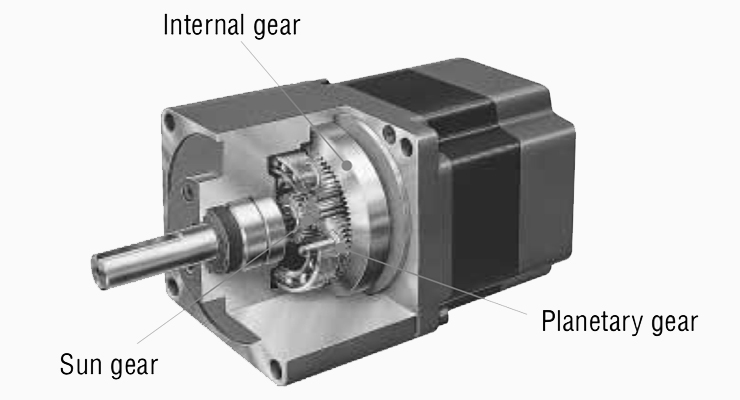

Reducers are standalone units that integrate gear, worm, and combined gear-worm transmissions within a robust casing. They are commonly utilized to reduce speed between the initial moving components and the operational machinery. The reducer harmonizes the speed and torque transmission between the power source and the working machine. Widely employed in contemporary machinery, they are especially favored for applications requiring low-speed, high-torque operation. The reducer achieves speed reduction by engaging a larger gear on the output shaft with a smaller gear on the input shaft. Multiple gear pairs may be used to attain the desired reduction ratio, with the transmission ratio defined by the teeth count ratio of the gears involved. The power source for the reducer can range from a DC motor to a stepper motor, a coreless motor, or a micro motor, with such devices also referred to as DC gear motors, stepper gear motors, coreless gear motors, or micro gear motors.

The geared stepper motor is an assembly of a reducer and a motor. While the motor is capable of high speeds with low torque and generates significant movement inertia, the reducer's role is to decrease this speed, thereby increasing torque and reducing inertia to meet the necessary operational parameters.

Every time there's a signal change, the motor turns a fixed angle, which makes stepper motors particularly useful in situations that require precise positioning. Imagine the vending machines we see everywhere: they use stepper motors to control the dispensing of items, ensuring that only one item drops at a time.

Sinbad Motor boasts over a decade of expertise in the stepper gear motor industry, offering clients an extensive array of custom motor prototype data. Furthermore, the company is adept at integrating precision planetary gearboxes with tailored reduction ratios or matching encoders to swiftly engineer micro transmission solutions that are perfectly aligned with customer requirements.

In essence, stepper motors offer control over movement length and speed. The distinction between stepper motors and geared stepper motors lies in the stepper's ability to maintain a constant speed and punctuality, allowing for the setting of duration and rotational velocity. Conversely, the speed of a geared stepper motor is determined by the reduction ratio, is not adjustable, and is inherently high-speed. While stepper motors are characterized by low torque, geared stepper motors boast high torque.

Editor: Carina

Post time: Apr-19-2024