A brushless DC motor (BLDC) is a motor that uses electronic commutation technology. It achieves precise speed and position control through precise electronic control, making the brushless DC motor more efficient and reliable. This electronic commutation technology eliminates brush friction and energy loss in traditional brushed DC motors, allowing them to operate more efficiently. Its working principle is based on electromagnetic induction and electronic commutation technology. Compared with traditional brushed DC motors, brushless DC motors achieve electronic commutation through built-in sensors and controllers, thereby achieving high efficiency, low noise and low maintenance operation.

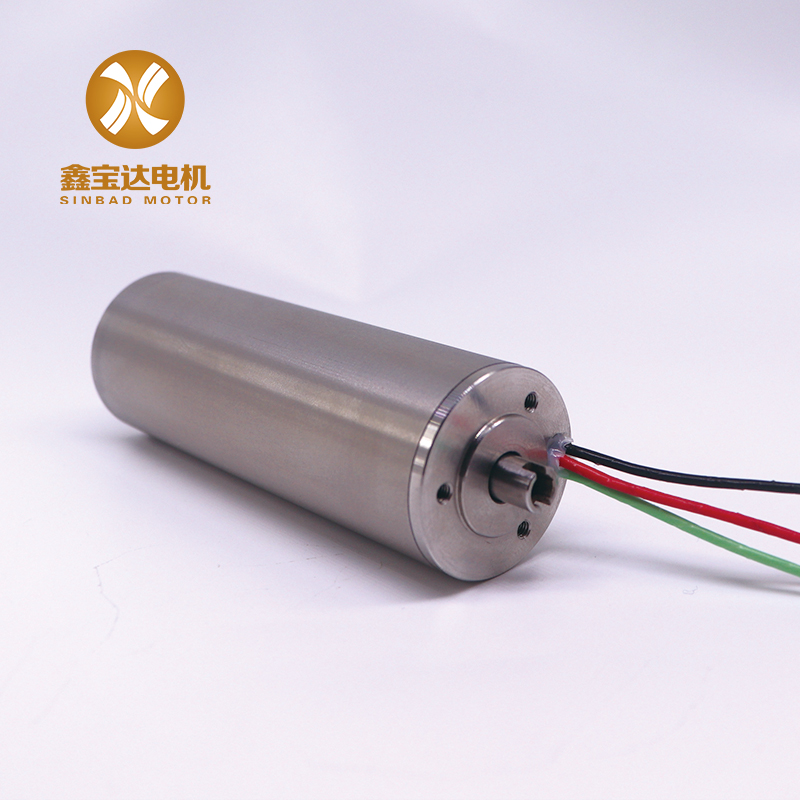

Brushless DC motors usually consist of a rotor, stator, sensors and controller. The rotor is usually made of permanent magnet material, while the stator contains coils of wire. When current passes through the stator coil, the magnetic field generated interacts with the permanent magnet material on the rotor, thereby generating torque to drive the rotor to rotate. Sensors are often used to detect the position and speed of the rotor so that the controller can accurately control the direction and magnitude of the current. The controller is the brain of the brushless motor. It uses feedback information from the sensor to achieve precise electronic commutation, thereby driving the motor to run efficiently.

The working process of the brushless DC motor can be divided into several stages: first, when the current passes through the stator coil, the generated magnetic field interacts with the permanent magnet material on the rotor to generate torque to drive the rotor to rotate. Second, the sensor detects the position and speed of the rotor and feeds the information back to the controller. The controller accurately controls the direction and size of the current based on the feedback information from the sensor to achieve accurate position and speed control of the rotor. Finally, based on the position and speed information of the rotor, the controller accurately controls the direction and magnitude of the current to achieve electronic commutation, thereby continuously driving the rotor to rotate.

Compared with traditional brushed DC motors, brushless DC motors have higher efficiency and reliability, so they have been widely used in many fields. In the automotive industry, our Sinbad brushless DC motors are used in the drive systems of electric vehicles. Their efficient and reliable performance enable electric vehicles to achieve longer cruising range and faster acceleration. In the field of home appliances, our Sinbad brushless DC motors are used in various home appliances, such as washing machines, vacuum cleaners, etc. Their low noise and high efficiency make home appliances more energy-saving and environmentally friendly. In addition, brushless DC motors are also widely used in industrial automation, aerospace, drones and other fields.

In general, brushless DC motors have become an important part of the modern electrification field with their advantages such as high efficiency, low noise, long life, and precise control. Their wide application in various fields will further promote brushless DC motor technology. development and innovation.

Post time: Apr-03-2024