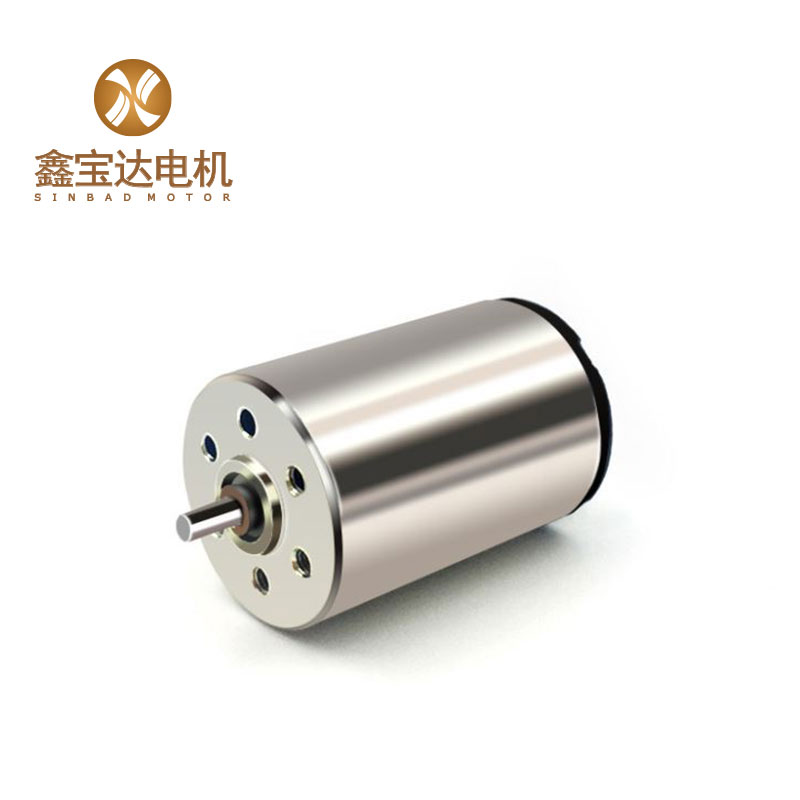

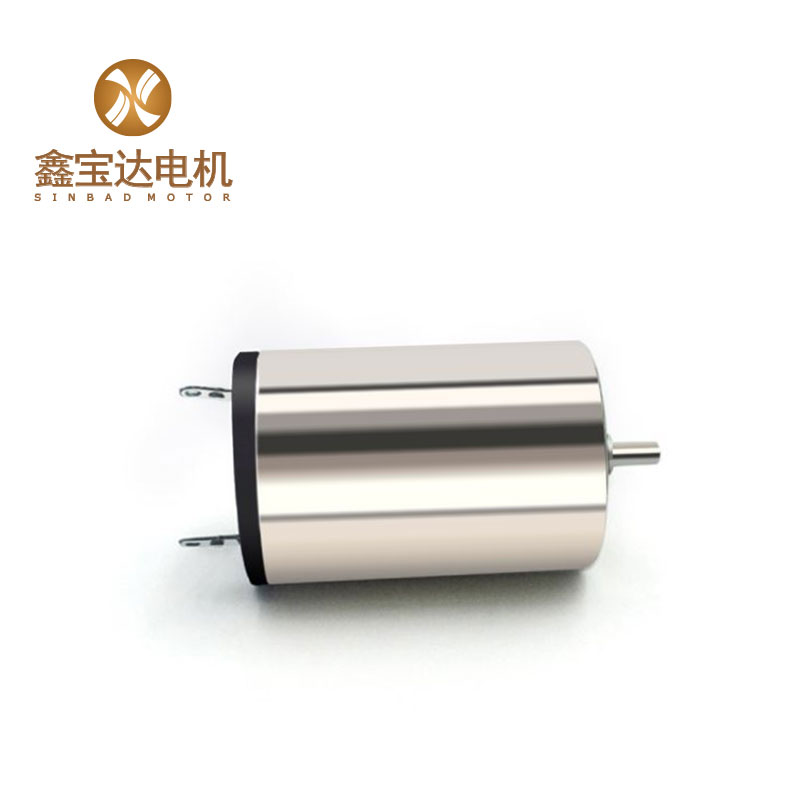

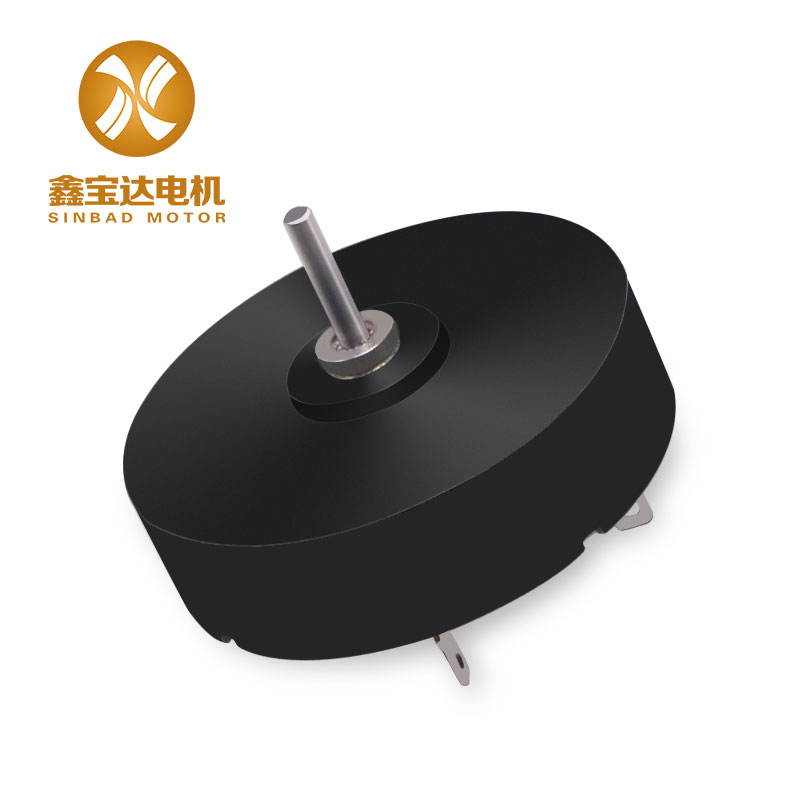

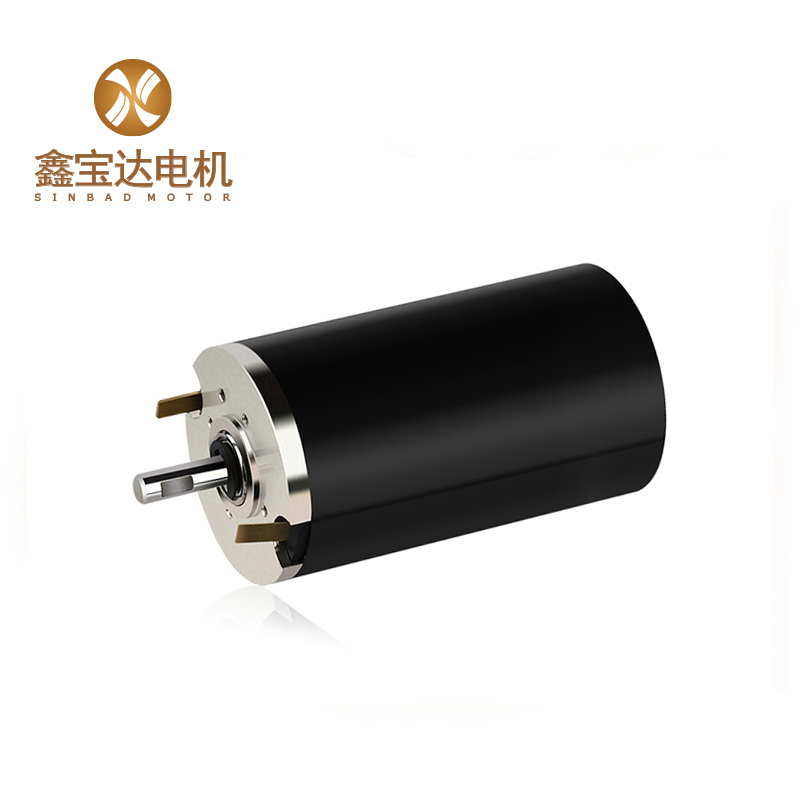

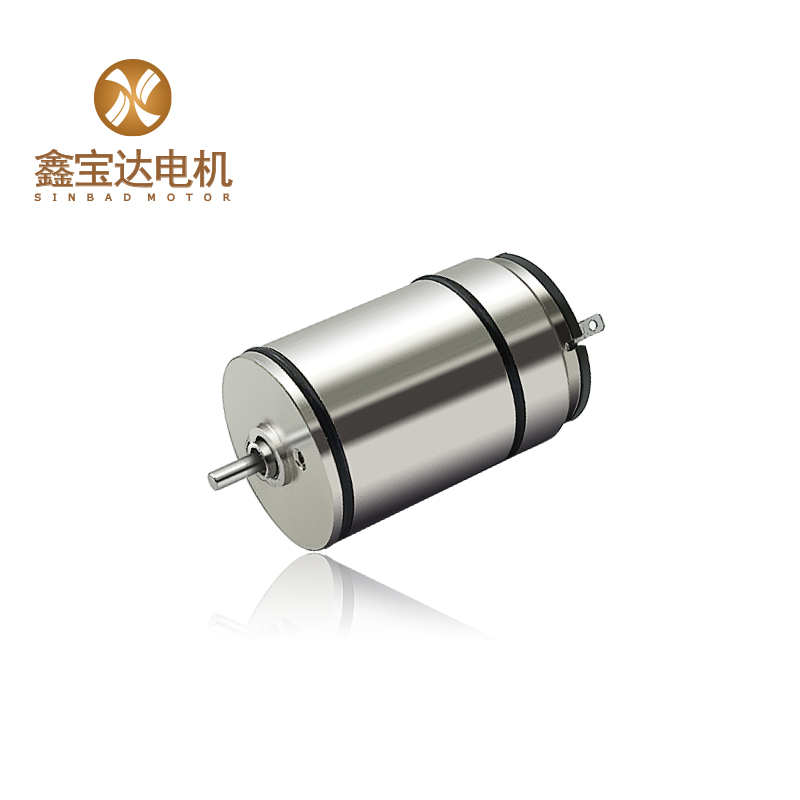

XBD-2030 Precious Metal Brushed DC Motor

Product Introduction

The XBD-2030 Precious Metal Brushed DC Motor is a highly efficient and reliable motor ideal for a wide range of industrial applications. Its superior conductivity and precious metal brushes provide excellent efficiency and performance, making it highly suitable for use in precision machinery and equipment. The motor delivers high torque output, providing precise control and increased power to various systems. It also features a smooth and quiet operation, making it a preferred choice for applications where noise is a concern. The motor's compact and lightweight design allows for easy integration into different systems, while its long operational lifespan ensures durability and reliability. Additionally, the XBD-2030 Precious Metal Brushed DC Motor can be customized to meet specific application requirements, offering greater versatility and flexibility. Furthermore, integrated gearbox and encoder options are available to further customize the motor performance to meet the needs of different industrial applications.

Application

Sinbad coreless motor have a wide range of application such as robots, drones, medical equipment, automobiles, information and communications, power tools, beauty equipment, precision instruments and military industry.

Advantage

The advantages of the XBD-2030 Precious Metal Brushed DC Motor are:

1. High efficiency and reliable performance due to its superior conductivity and precious metal brushes.

2. Excellent torque output, providing precise control and increased power to various systems.

3. Smooth and quiet operation, making it suitable for applications where noise is a concern.

4. Compact and lightweight design, allowing for easy integration into different systems.

5. Long operational lifespan, ensuring durability and reliability.

6. Customizable to meet specific application requirements, offering greater versatility and flexibility.

7. Integrated gearbox and encoder options available to further customize motor performance for different industrial applications.

Parameter

| Motor model 2030 | ||||||

| Brush material precious metal | ||||||

| At nominal | ||||||

| Nominal voltage | V |

6 |

9 |

12 |

15 |

24 |

| Nominal speed | rpm |

8379 |

8550 |

10260 |

8550 |

7781 |

| Nominal current | A |

1.05 |

0.77 |

0.64 |

0.29 |

0.16 |

| Nominal torque | mNm |

5.75 |

6.29 |

5.71 |

3.76 |

3.78 |

|

Free load |

||||||

| No-load speed | rpm |

9800 |

10000 |

12000 |

10000 |

9100 |

| No-load current | mA |

60 |

38 |

40 |

20 |

8 |

|

At max efficiency |

||||||

| Max efficiency | % |

82.2 |

83.5 |

81.4 |

80.3 |

83.3 |

| Speed | rpm |

8967 |

9200 |

10920 |

9050 |

8372 |

| Current | A |

0.607 |

0.445 |

0.414 |

0.194 |

0.091 |

| Torque | mNm |

3.2 |

3.5 |

3.5 |

2.5 |

2.1 |

|

At max output power |

||||||

| Max output power | W |

10.2 |

11.3 |

12.4 |

6.8 |

6.0 |

| Speed | rpm |

4900 |

5000 |

6000 |

5000 |

4550 |

| Current | A |

3.5 |

2.6 |

2.1 |

0.9 |

1.0 |

| Torque | mNm |

19.8 |

21.7 |

19.7 |

13.0 |

13.0 |

|

At stall |

||||||

| Stall current | A |

6.90 |

5.12 |

4.20 |

1.85 |

1.05 |

| Stall torque | mNm |

39.6 |

43.4 |

39.3 |

25.9 |

26.0 |

|

Motor constants |

||||||

| Terminal resistance | Ω |

0.87 |

1.76 |

2.86 |

8.11 |

22.90 |

| Terminal inductance | mH |

0.14 |

0.29 |

0.51 |

0.86 |

1.90 |

| Torque constant | mNm/A |

5.80 |

8.53 |

9.46 |

14.17 |

25.00 |

| Speed constant | rpm/V |

1633.3 |

1111.1 |

1000.0 |

666.7 |

379.2 |

| Speed/Torque constant | rpm/mNm |

247.2 |

230.7 |

305.0 |

385.7 |

349.4 |

| Mechanical time constant | ms |

6.51 |

6.08 |

7.63 |

9.65 |

8.74 |

| Rotor inertia | g·cm² |

2.52 |

2.52 |

2.39 |

2.39 |

2.42 |

| Number of pole pairs 1 | ||||||

| Number of phase 5 | ||||||

| Weight of motor | g | 48 | ||||

| Typical noise level | dB | ≤38 | ||||

Samples

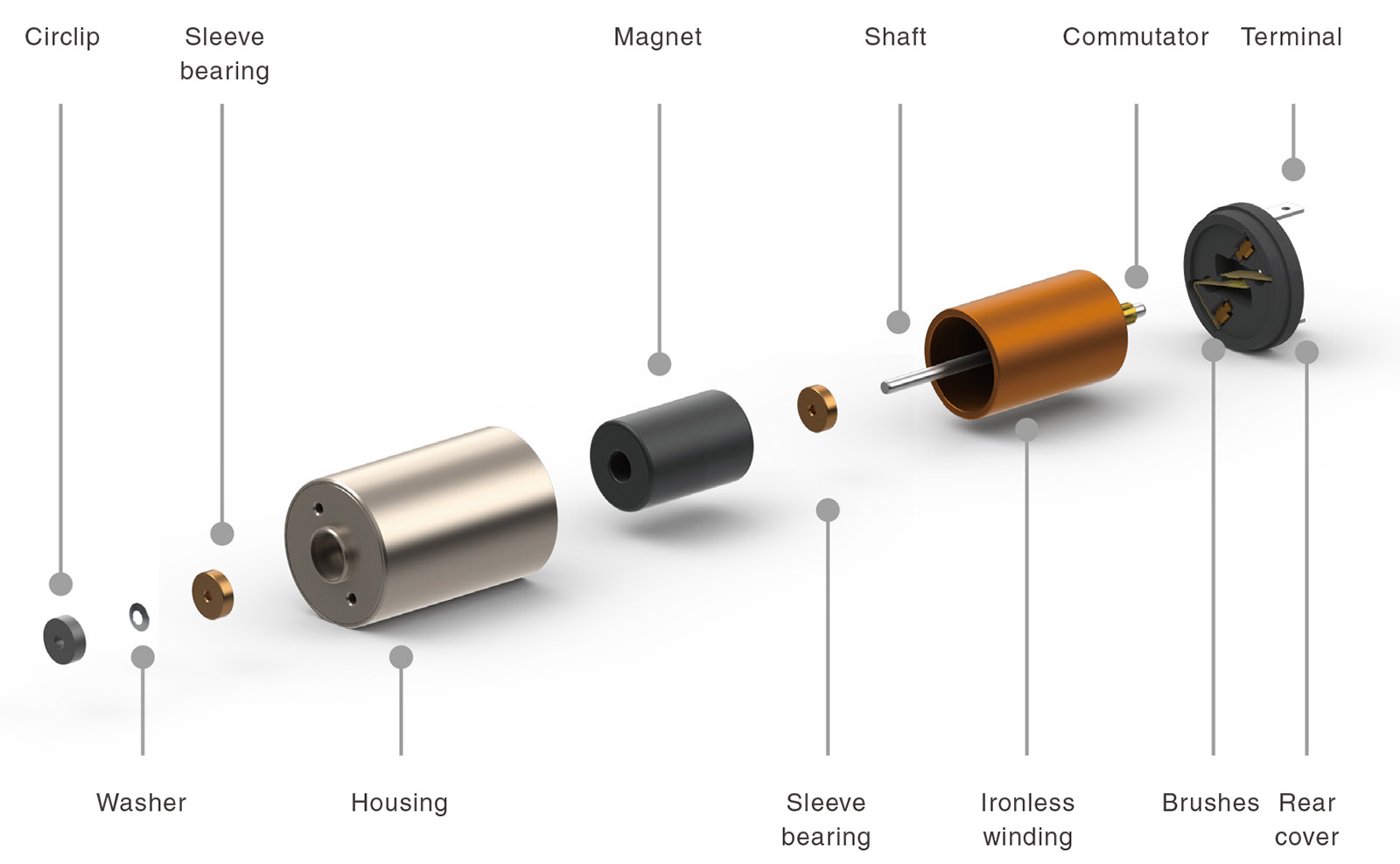

Structures

FAQ

A: Yes. We are a manufacturer specializing in Coreless DC Motor since 2011.

A: We have QC team comply with TQM, each step is in compliance to the standards.

A: Normally, MOQ=100pcs. But small batch 3-5 piece is accepted.

A: Sample is available for you. please contact us for details. Once we charge you sample fee, please feel easy, it will be refund when you place mass order.

A: send us inquiry → receive our quotation → negotiate details → confirm the sample → sign contract/deposit → mass production → cargo ready → balance/delivery → further cooperation.

A: Delivery time depends on the quantity you order. usually it takes 30~45 calendar days.

A: We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

A: We accept payment by T/T, PayPal, the other payment ways also could be accepted,Please contact us before you pay by the other payment ways. Also 30-50% deposit is available, the balance money should be paid before shipping.

Are you fascinated by electric motors and interested in the science behind their function? In this article, we explore the fascinating world of motor science knowledge and uncover the secrets behind these powerful machines.

First, let's define what a motor is. An electric motor is a machine that converts electrical, chemical or thermal energy into mechanical energy. From household appliances to transportation systems, electric motors are used in countless applications across various industries. The basic principle behind an electric motor is the interaction between a magnetic field and an electric current.

There are two main types of motors: AC motors and DC motors. AC motors are powered by alternating current while DC motors are powered by direct current. AC motors are often used in large applications such as industrial machines and electric trains. Meanwhile, DC motors are used in small applications such as home appliances and handheld devices.

The core component of an electric motor is the rotor-stator system. The rotor is the rotating part of the motor while the stator is the stationary part. The stator contains the electrical windings and the rotor contains the magnetic field generating components. When current passes through the windings of the stator, it creates a magnetic field, which causes motion in the rotor, causing rotation.

A motor is only as strong as its torque and speed. Torque is the rotational force produced by a motor, while speed is the rate at which the motor rotates. Motors with higher torque can generate more force, making them suitable for heavy-duty applications such as industrial machinery. Meanwhile, higher speed motors are used in applications such as cooling systems or fans.

An important aspect of motor design is its efficiency. The efficiency of a motor is the ratio of its output power to its input power, with more efficient motors delivering more output power per unit of input power. Efficient motor design minimizes energy loss through friction, heat and other factors. Energy-efficient motors not only save energy, but also reduce operating costs and carbon emissions.

Knowledge of motor science continues to evolve, leading to the creation of new, more efficient motor designs. One of these developments is the brushless DC motor, which offers greater efficiency, reliability and longer life than conventional brushed DC motors. Brushless motors use a different design, forgoing the brushes and commutator, which can lead to wear and tear over time.

In summary, knowledge of electric motor science continues to advance, leading to more efficient, powerful and innovative electric motors. Electric motors have become an integral part of our everyday lives, powering everything from household appliances to transportation systems. Understanding the science behind electric motors is critical to creating improved designs that move the world forward while minimizing environmental impact. Advances in motor science will continue to shape every industry that relies on electric motors to provide power and motion.