XBD-2431 replace Pittman portescap rotalink low price magnets winding machine micro multiwii

Product Introduction

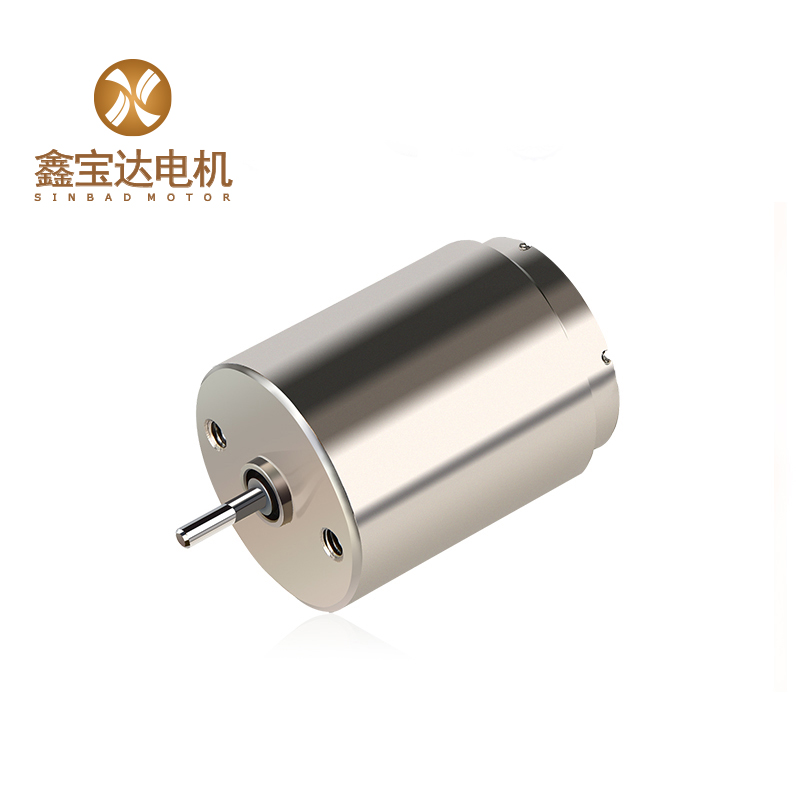

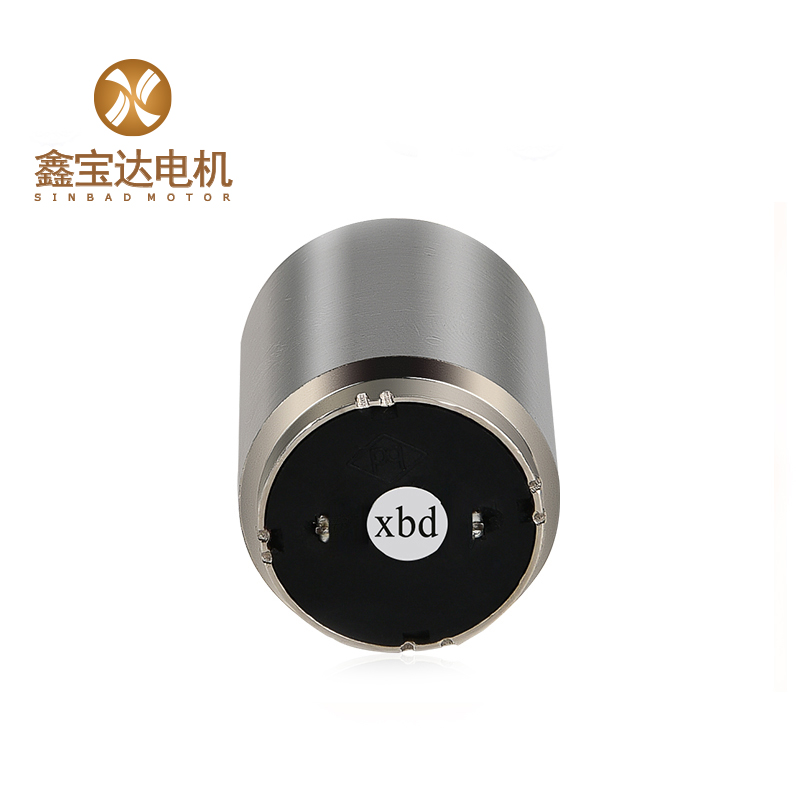

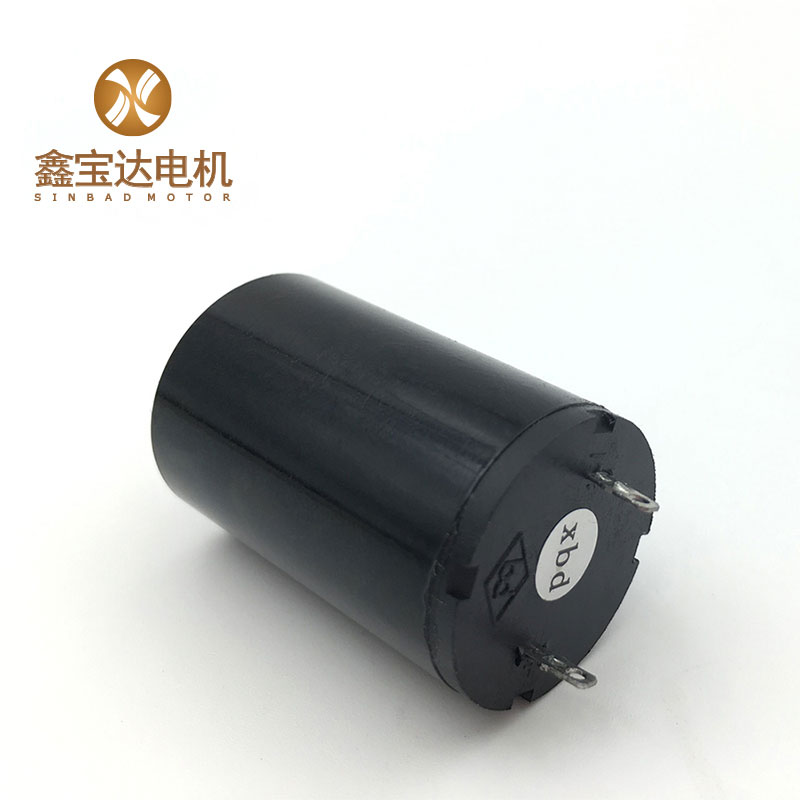

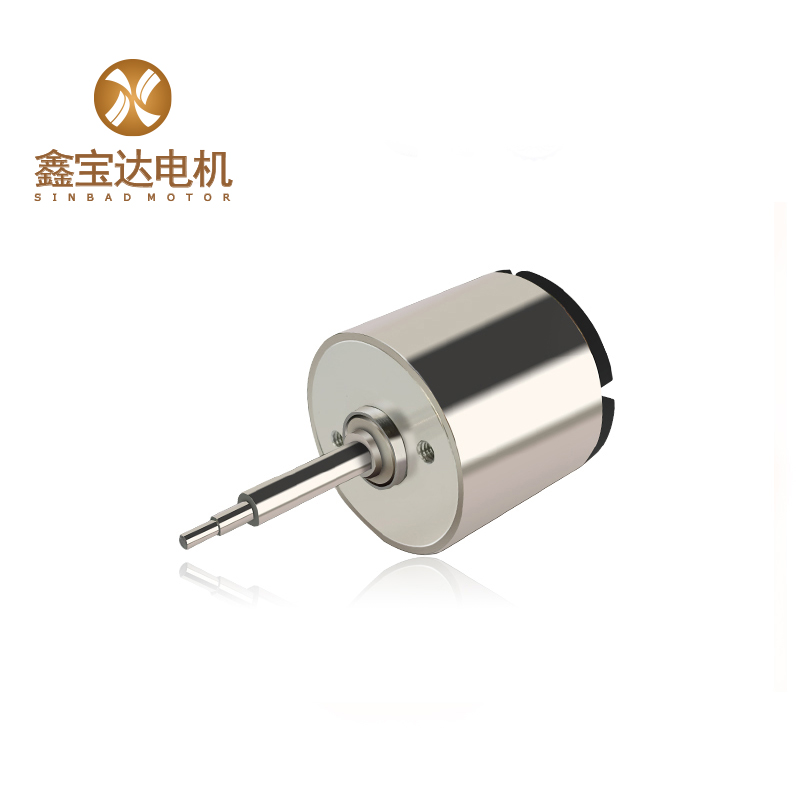

The XBD-2431 Silver Metal Casing motor demonstrates the advantages of precious metal motors in certain special environments. Thanks to the excellent corrosion resistance of precious metal materials, this motor maintains good performance and exhibits strong adaptability in special environments such as high temperatures, high humidity, and corrosive gas environments. As science and technology continue to advance, the demands for motor performance are increasing, and the application prospects for precious metal motors are constantly expanding. For instance, with the rapid development of new energy vehicles, aerospace, and other fields, the requirements for motor performance are becoming higher. Our Sinbad precious metal motors have broad application prospects in these areas.

Application

Sinbad coreless motor have a wide range of application such as robots, drones, medical equipment, automobiles, information and communications, power tools, beauty equipment, precision instruments and military industry.

Advantage

The advantages of the XBD-2431 Precious Metal Brushed DC Motor are:

1. High-performance and reliable motor design.

2. Efficient and reliable performance thanks to superior conductivity and precious metal brushes.

3. High torque output for precise control and increased power.

4. Smooth and quiet operation for noise-sensitive applications.

5. Compact and lightweight design for easy integration.

6. Long operational lifespan for durability and reliability.

7. Customizable to meet specific application requirements.

Parameter

| Motor model 2431 | |||||

| Brush material precious metal | |||||

| At nominal | |||||

| Nominal voltage | V |

6 |

9 |

12 |

24 |

| Nominal speed | rpm |

7298 |

9078 |

8900 |

8811 |

| Nominal current | A |

0.50 |

0.24 |

0.46 |

0.16 |

| Nominal torque | mNm |

3.09 |

1.81 |

4.82 |

3.39 |

|

Free load |

|||||

| No-load speed | rpm |

8200 |

10200 |

10000 |

9900 |

| No-load current | mA |

50 |

25 |

40 |

14 |

|

At max efficiency |

|||||

| Max efficiency | % |

79.2 |

78.9 |

80.8 |

80.7 |

| Speed | rpm |

7380 |

9180 |

9100 |

9009 |

| Current | A |

0.457 |

0.223 |

0.387 |

0.135 |

| Torque | mNm |

2.8 |

1.6 |

3.9 |

2.8 |

|

At max output power |

|||||

| Max output power | W |

6.0 |

4.4 |

11.5 |

8.0 |

| Speed | rpm |

4100 |

5100 |

5000 |

4950 |

| Current | A |

2.1 |

1.0 |

2.0 |

0.7 |

| Torque | mNm |

14.0 |

8.2 |

21.9 |

15.4 |

|

At stall |

|||||

| Stall current | A |

4.12 |

2.00 |

3.90 |

1.36 |

| Stall torque | mNm |

28.1 |

16.4 |

43.8 |

30.8 |

|

Motor constants |

|||||

| Terminal resistance | Ω |

1.46 |

4.50 |

3.08 |

17.65 |

| Terminal inductance | mH |

0.160 |

0.530 |

0.450 |

1.700 |

| Torque constant | mNm/A |

6.90 |

8.32 |

11.34 |

22.91 |

| Speed constant | rpm/V |

1366.7 |

1133.3 |

833.3 |

412.5 |

| Speed/Torque constant | rpm/mNm |

291.9 |

620.7 |

228.4 |

321.0 |

| Mechanical time constant | ms |

14.22 |

30.23 |

12.27 |

16.01 |

| Rotor inertia | g·cm² |

4.65 |

4.65 |

5.13 |

4.76 |

| Number of pole pairs 1 | |||||

| Number of phase 5 | |||||

| Weight of motor | g | 68 | |||

| Typical noise level | dB | ≤38 | |||

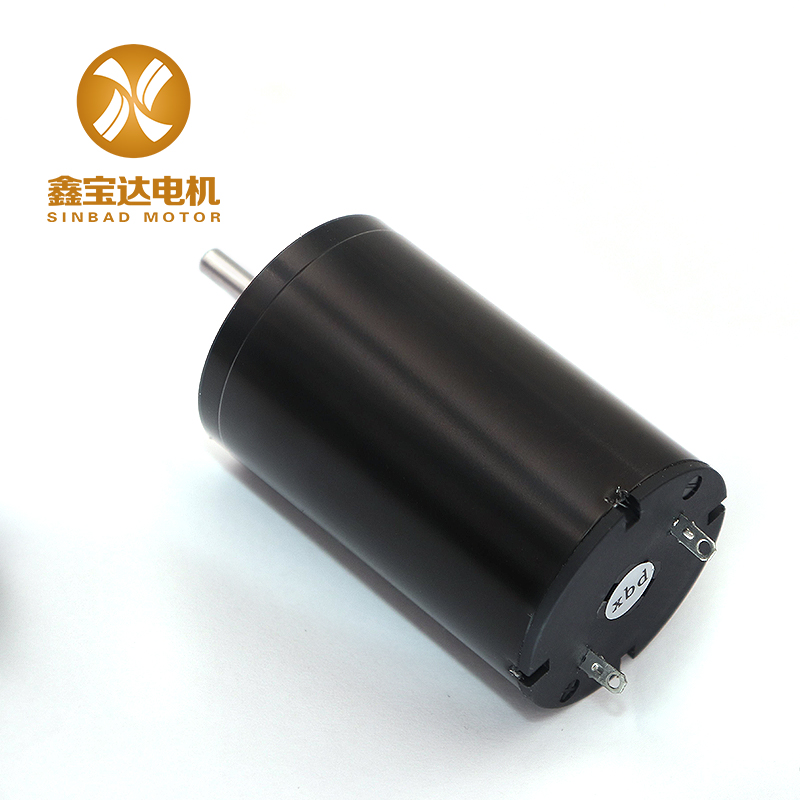

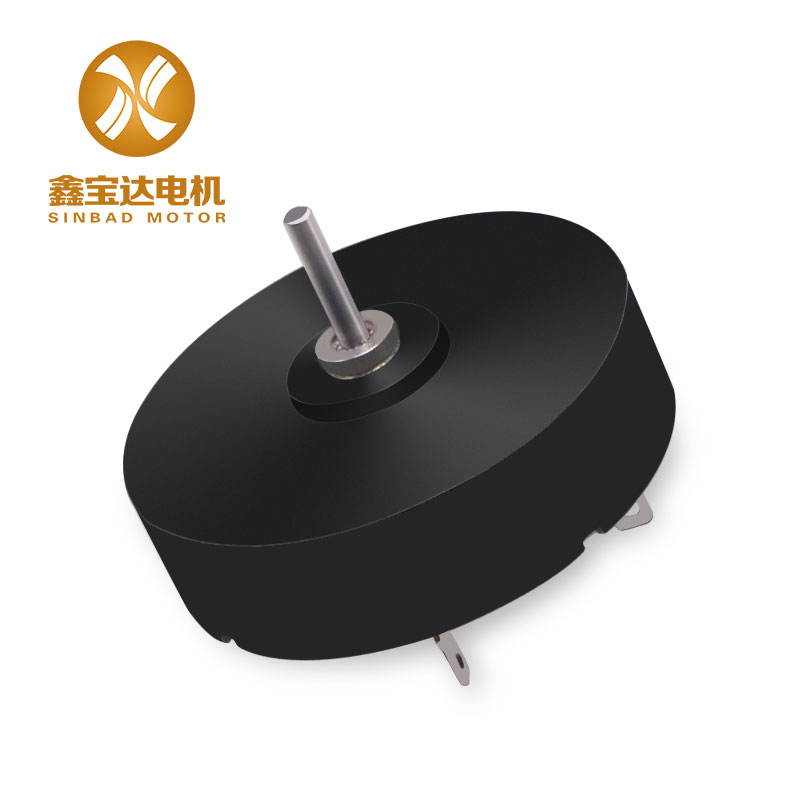

Samples

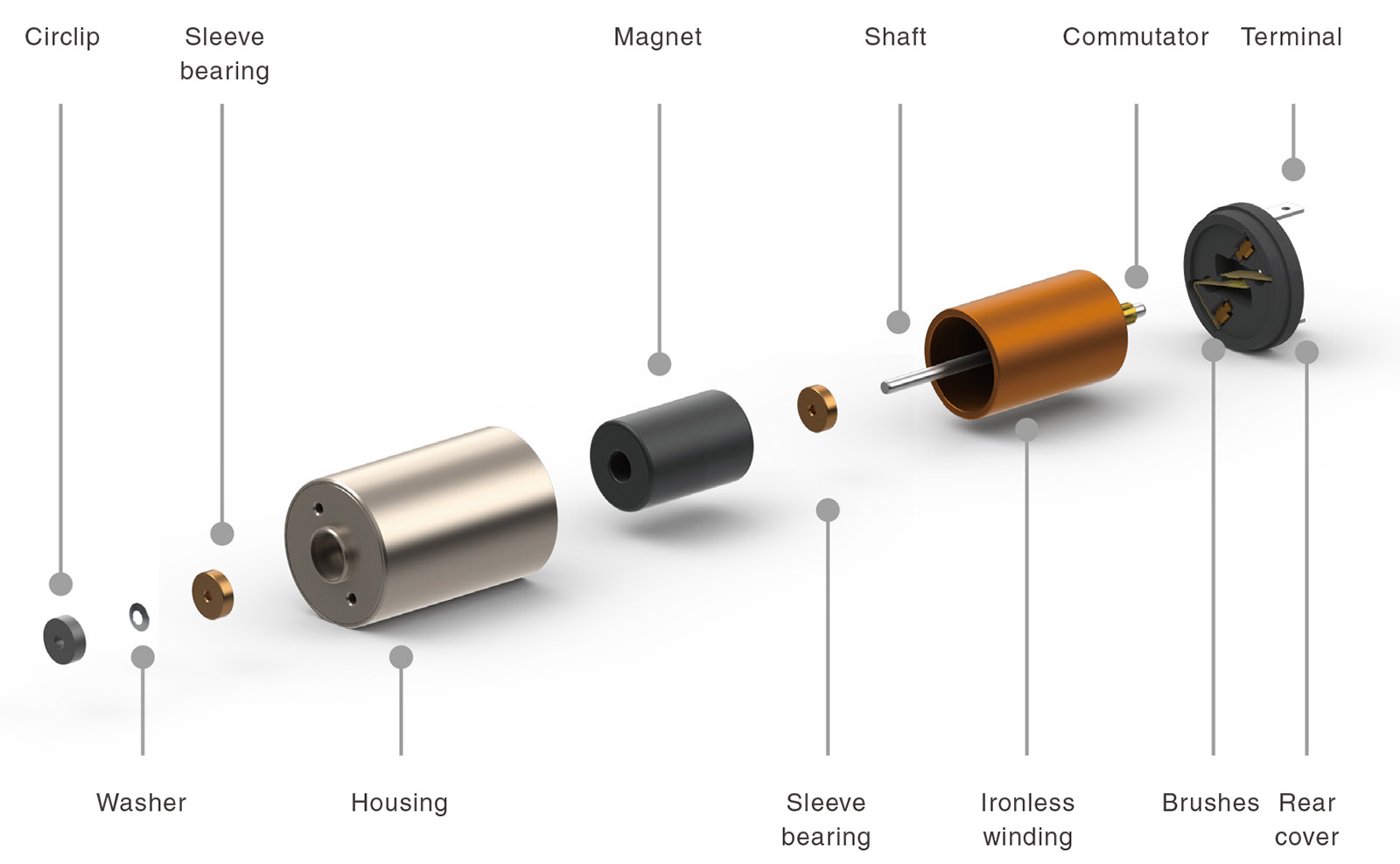

Structures

FAQ

A: Yes. We are a manufacturer specializing in Coreless DC Motor since 2011.

A: We have QC team comply with TQM, each step is in compliance to the standards.

A: Normally, MOQ=100pcs. But small batch 3-5 piece is accepted.

A: Sample is available for you. please contact us for details. Once we charge you sample fee, please feel easy, it will be refund when you place mass order.

A: send us inquiry → receive our quotation → negotiate details → confirm the sample → sign contract/deposit → mass production → cargo ready → balance/delivery → further cooperation.

A: Delivery time depends on the quantity you order. usually it takes 30~45 calendar days.

A: We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

A: We accept payment by T/T, PayPal, the other payment ways also could be accepted,Please contact us before you pay by the other payment ways. Also 30-50% deposit is available, the balance money should be paid before shipping.

Motor Care and Maintenance: A Guide to Keeping Your Motor Running Smoothly

Motors are an integral part of our lives. From automobiles to industrial machinery to home appliances, electric motors play a vital role in powering the devices we use every day.

But like any machine, motors require regular care and maintenance to keep them in top condition. By properly maintaining your motor, you can extend its life and prevent costly failures.

Here are some motor care and maintenance tips to help keep your motor running smoothly:

1. Keep it clean: One of the easiest ways to maintain your motor is to keep it clean. Over time, dust and debris can accumulate on the motor, causing it to overheat and eventually fail. Use a soft brush or cloth to remove any dust or dirt that has accumulated on the surface of the motor.

2. Check the lubrication: the motor needs proper lubrication to work properly. Make sure to check the oil level regularly and replace it if needed. You can usually find the oil fill location in your motor manual. Be sure to use the recommended type of oil for your motor.

3. Check the electrical components: Over time, the electrical components inside the motor will age and cause failures. Perform a cursory inspection of insulation, wiring and connections to ensure there are no signs of wear or corrosion.

4. Monitor motor temperature: Overheating is one of the most common causes of motor failure. Make sure to monitor the temperature of the motor regularly and address any overheating issues immediately. Allow the motor to cool down before continuing to use it.

5. Schedule regular maintenance: In order to keep your motor running at peak performance, it is necessary to schedule regular maintenance. This should include professional inspection, cleaning and lubrication. A professional auto service technician can perform this service for you.

By following these motor maintenance and care tips, you can help extend the life of your motor and prevent costly failures. Remember that a motor is an investment, and proper maintenance can save you money in the long run. So be sure to give your motor the attention it deserves.