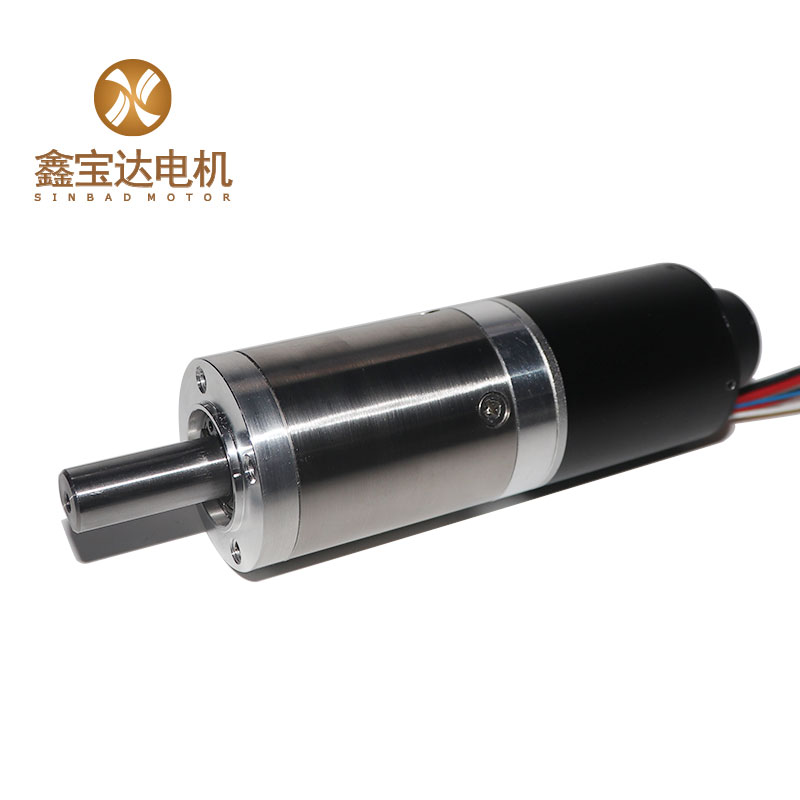

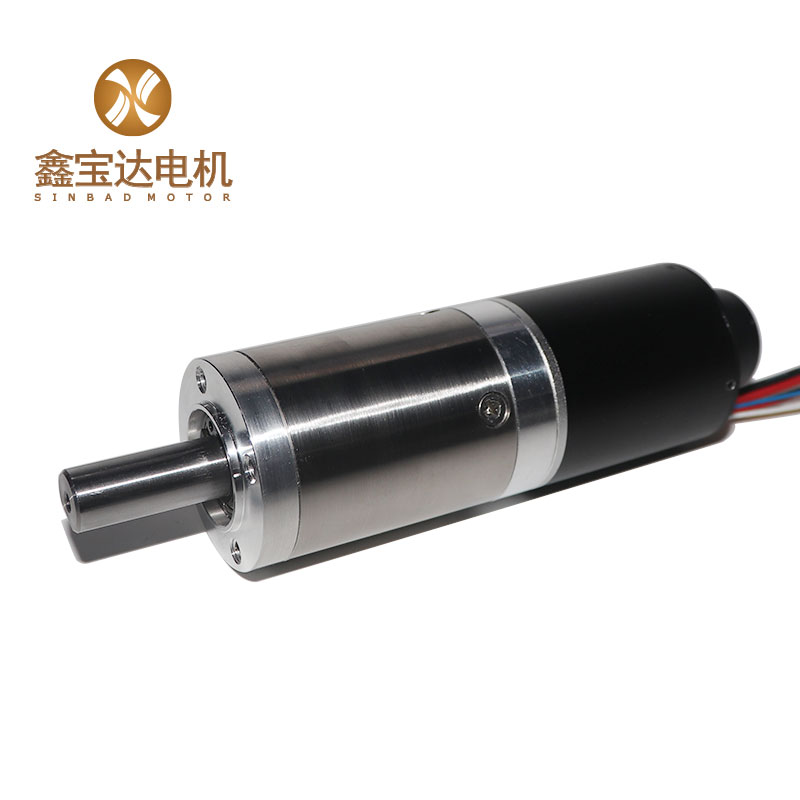

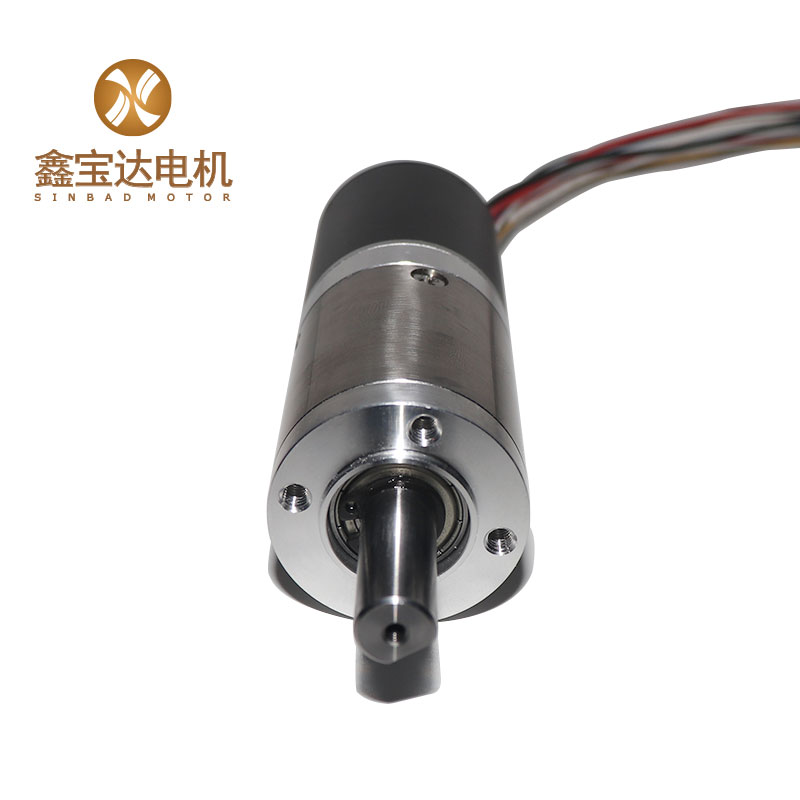

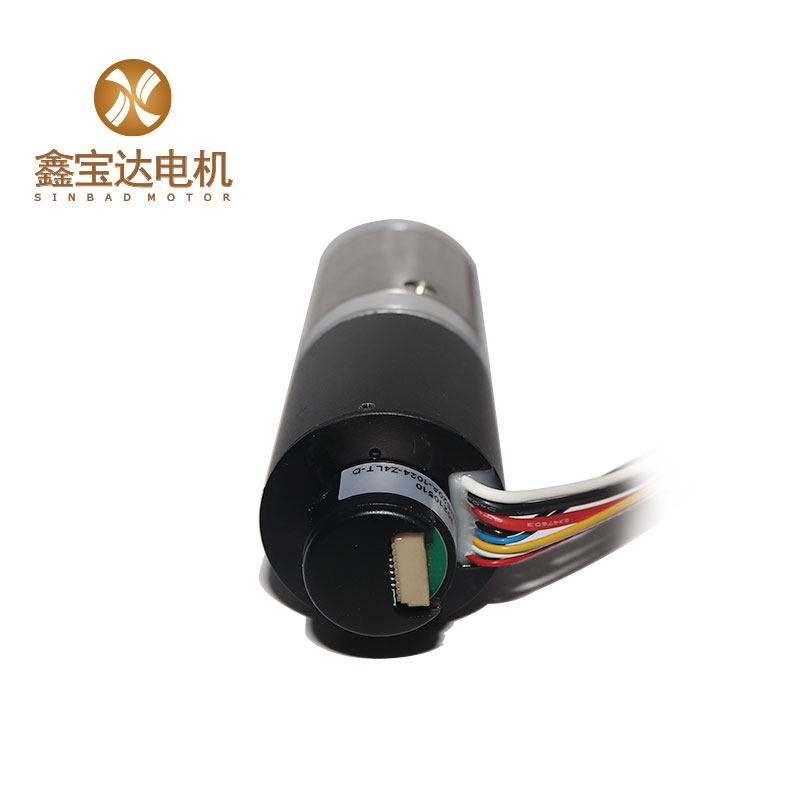

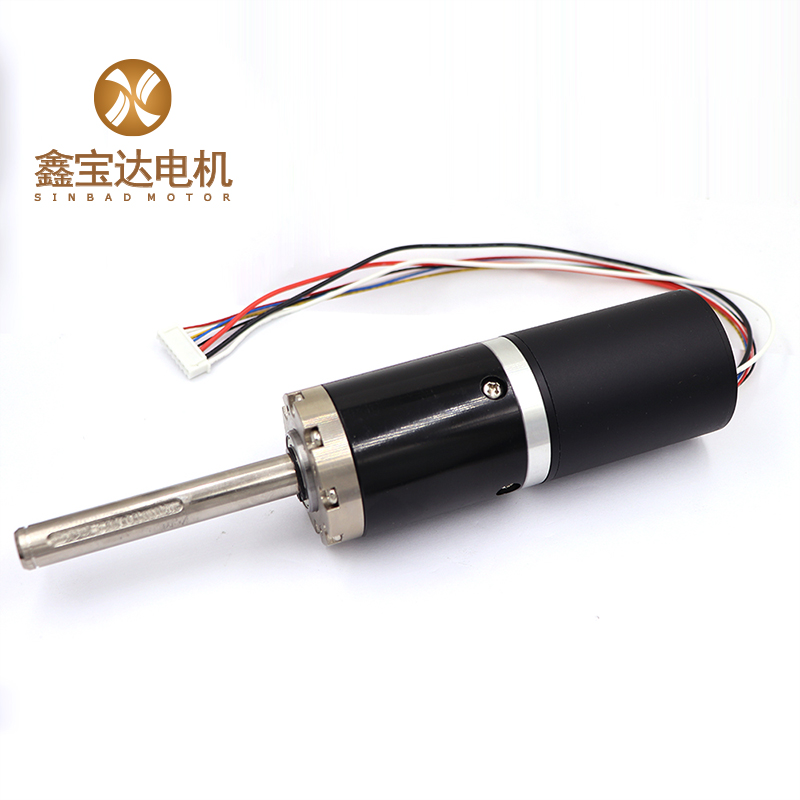

High Efficiency Low Noise Brushless DC Motor For Tattoo Machine 3542

Product Introduction

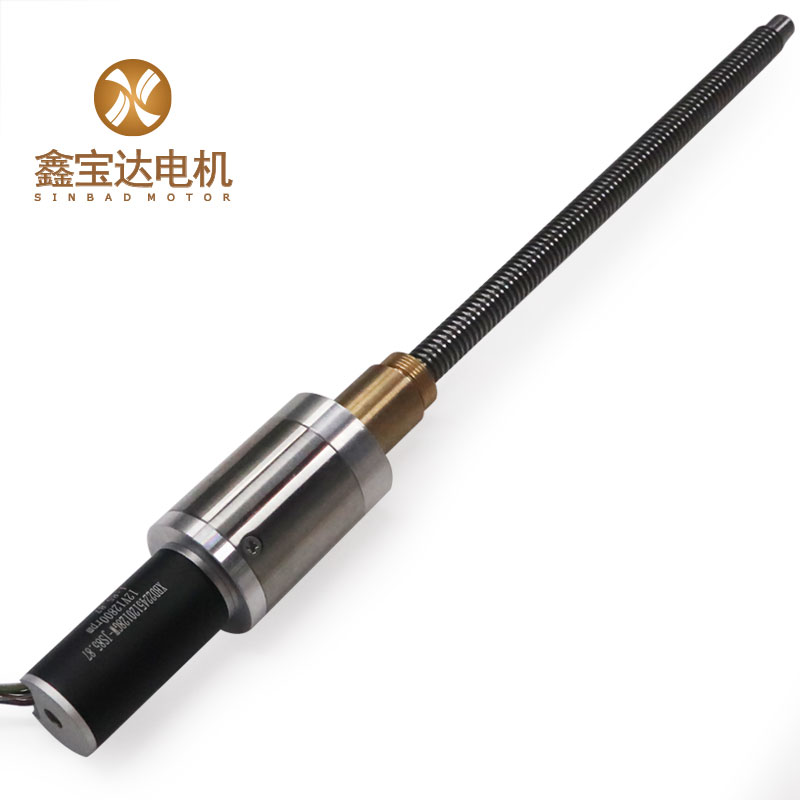

The XBD-3542 is a coreless brushless DC motor that is popular for its high torque output. With its specialized design and construction, this motor doesn't suffer from the cogging and limitations of traditional iron-core motors, instead providing a smoother rotational experience. Delivering an impressive amount of torque despite its compact size, this motor is perfect for high-precision equipment requiring a reliable power source that won't let you down. Thanks to its superior performance, efficiency, and longevity, the XBD-3542 is the ideal choice for robotics, medical devices, and other applications where the focus is on precision and accuracy.

Application

Sinbad coreless motor have a wide range of application such as robots, drones, medical equipment, automobiles, information and communications, power tools, beauty equipment, precision instruments and military industry.

Advantage

The advantages of the XBD-3542 Coreless Brushless DC Motor can be broken down into several key points:

1. Coreless design: The motor's coreless construction provides a smoother rotational experience and reduces the risk of cogging, which can result in improved efficiency and reduced noise levels.

2. Brushless construction: The motor operates using a brushless design, which eliminates brushes and commutators. This not only improves efficiency but also increases the longevity of the motor.

3. High torque output: Despite its compact size, the XBD-3542 delivers a high amount of torque, making it suitable for high-precision equipment that requires reliable power. The motor's high torque output also makes it ideal for heavy-duty applications where a powerful motor is necessary.

Overall, these advantages make the XBD-3542 Coreless Brushless DC Motor a dependable and effective choice for a wide range of applications. Its coreless brushless design and high torque output make it particularly well-suited for use in robotics, medical devices, and other applications where precision and power are key considerations.

Parameter

| Motor model 3542 | |||||

| At nominal | |||||

| Nominal voltage | V |

12 |

18 |

24 |

36 |

| Nominal speed | rpm |

4868 |

5610 |

5412 |

5115 |

| Nominal current | A |

3.11 |

2.02 |

1.55 |

1.01 |

| Nominal torque | mNm |

51.83 |

41.36 |

42.62 |

42.78 |

|

Free load |

|||||

| No-load speed | rpm |

5900 |

6800 |

6560 |

6200 |

| No-load current | mA |

380 |

330 |

280 |

200 |

|

At max efficiency |

|||||

| Max efficiency | % |

71.6 |

67.0 |

65.1 |

63.3 |

| Speed | rpm |

4986 |

5746 |

5510 |

5146 |

| Current | A |

2.801 |

1.829 |

1.438 |

0.982 |

| Torque | mNm |

45.90 |

36.64 |

38.96 |

39.11 |

|

At max output power |

|||||

| Max output power | W |

45.7 |

42.1 |

41.8 |

39.7 |

| Speed | rpm |

2950 |

3400 |

3280 |

3100 |

| Current | A |

8.2 |

5.2 |

3.9 |

2.5 |

| Torque | mNm |

148.10 |

118.18 |

121.76 |

122.22 |

|

At stall |

|||||

| Stall current | A |

16.00 |

10.00 |

7.52 |

4.80 |

| Stall torque | mNm |

296.20 |

236.37 |

243.52 |

244.43 |

|

Motor constants |

|||||

| Terminal resistance | Ω |

0.75 |

1.80 |

3.19 |

7.50 |

| Terminal inductance | mH |

0.190 |

0.385 |

0.680 |

1.575 |

| Torque constant | mNm/A |

18.96 |

24.44 |

33.64 |

53.14 |

| Speed constant | rpm/V |

491.7 |

377.8 |

273.3 |

172.2 |

| Speed/Torque constant | rpm/mNm |

19.9 |

28.8 |

26.9 |

25.4 |

| Mechanical time constant | ms |

3.19 |

4.61 |

4.32 |

4.06 |

| Rotor inertia | g·cm² |

15.30 |

15.30 |

15.30 |

15.30 |

| Number of pole pairs 1 | |||||

| Number of phase 3 | |||||

| Weight of motor | g | 188.6 | |||

| Typical noise level | dB | ≤45 | |||

Samples

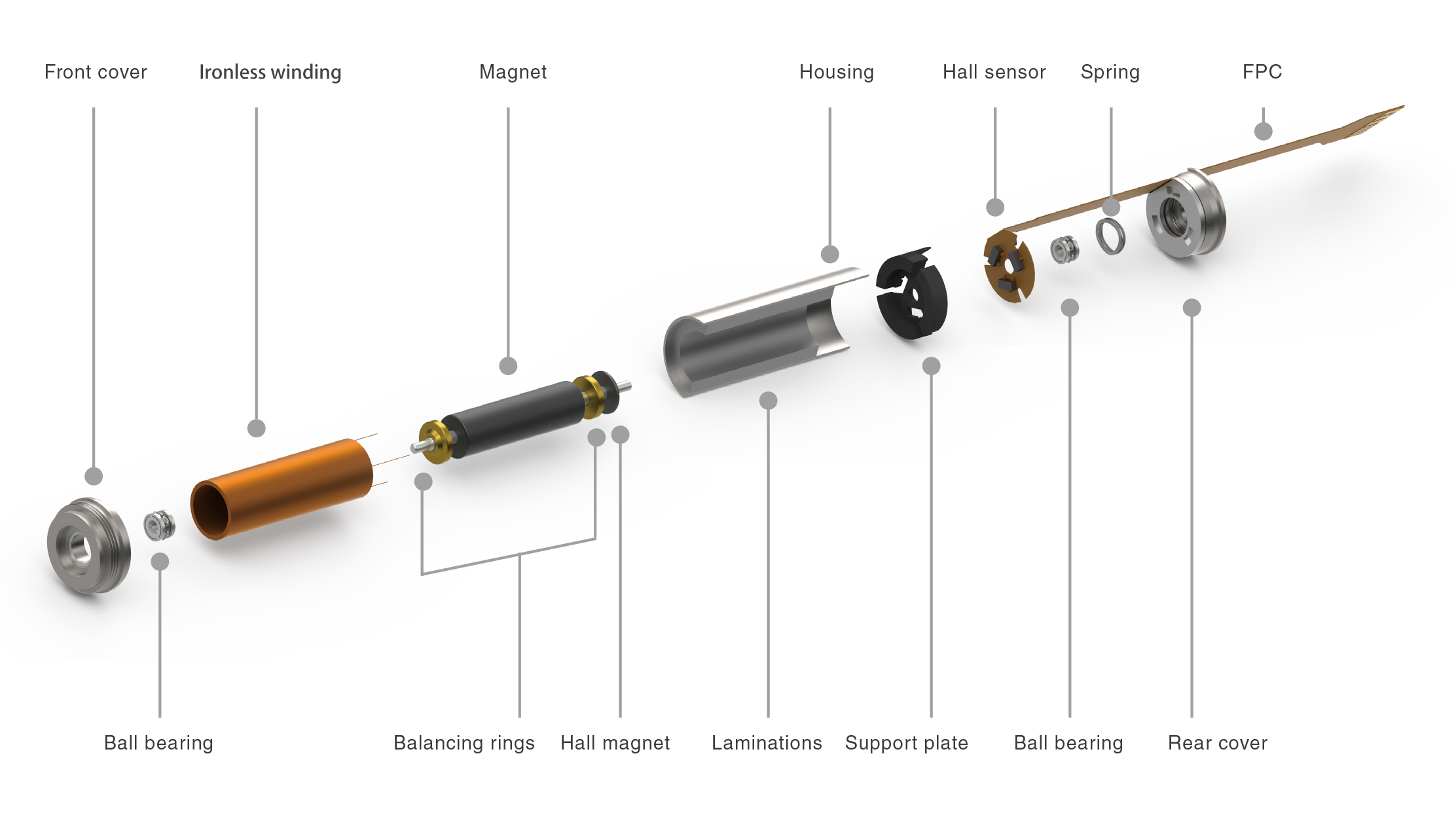

Structures

FAQ

A: Yes. We are a manufacturer specializing in Coreless DC Motor since 2011.

A: We have QC team comply with TQM, each step is in compliance to the standards.

A: Normally, MOQ=100pcs. But small batch 3-5 piece is accepted.

A: Sample is available for you. please contact us for details. Once we charge you sample fee, please feel easy, it will be refund when you place mass order.

A: send us inquiry → receive our quotation → negotiate details → confirm the sample → sign contract/deposit → mass production → cargo ready → balance/delivery → further cooperation.

A: Delivery time depends on the quantity you order. usually it takes 30~45 calendar days.

A: We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

A: We accept payment by T/T, PayPal, the other payment ways also could be accepted,Please contact us before you pay by the other payment ways. Also 30-50% deposit is available, the balance money should be paid before shipping.

A coreless brushless DC motor is a motor used in a wide variety of applications, from consumer electronics to industrial machinery. This motor is popular for its high efficiency, reliability and durability.

One of the main features of an ironless BLDC motor is that it has no iron core. This means the motor does not have the traditional iron core found in other types of motors. Instead, the motor uses copper or aluminum wire wrapped around a cylindrical base. This coiled wire acts as the armature of the motor.

Another feature of the coreless BLDC motor is that it is brushless. This means that the motor does not rely on brushes to transfer current to the motor rotor. Instead, the motor's rotor consists of magnets that interact with the armature's magnetic field to generate torque.

Coreless BLDC motors are more efficient than other types of motors due to the lack of brushes and iron core. This is because the armature of the motor is lighter and the motor generates less heat due to the lower resistance. Therefore, the motor can run at high speed with minimal energy loss.

Additionally, coreless BLDC motors are much quieter than other types of motors. This is because the design of the motor eliminates the noise generated by the brushes and iron core. This makes the motor ideal for applications requiring quiet operation.

Due to their design, coreless BLDC motors also last longer. Since the motor has no brushes, there is no wear on the armature of the motor. Also, no iron core means no magnetic fields that would cause the motor to wear out over time. Therefore, the motor lasts longer than other types of motors.

Finally, coreless brushless DC motors are versatile. It can be used in a wide range of applications including robotics, medical devices, aerospace equipment and industrial machinery. The efficiency, reliability and durability of this motor make it an excellent choice for these applications.

In summary, a coreless brushless DC motor is a motor that has several advantages over other types of motors. Its absence of iron cores and brushes, high efficiency, quiet operation, long life and versatility make it an attractive choice for a wide range of applications. As the technology continues to improve, it is likely that ironless brushless DC motors will become more popular and widely used.