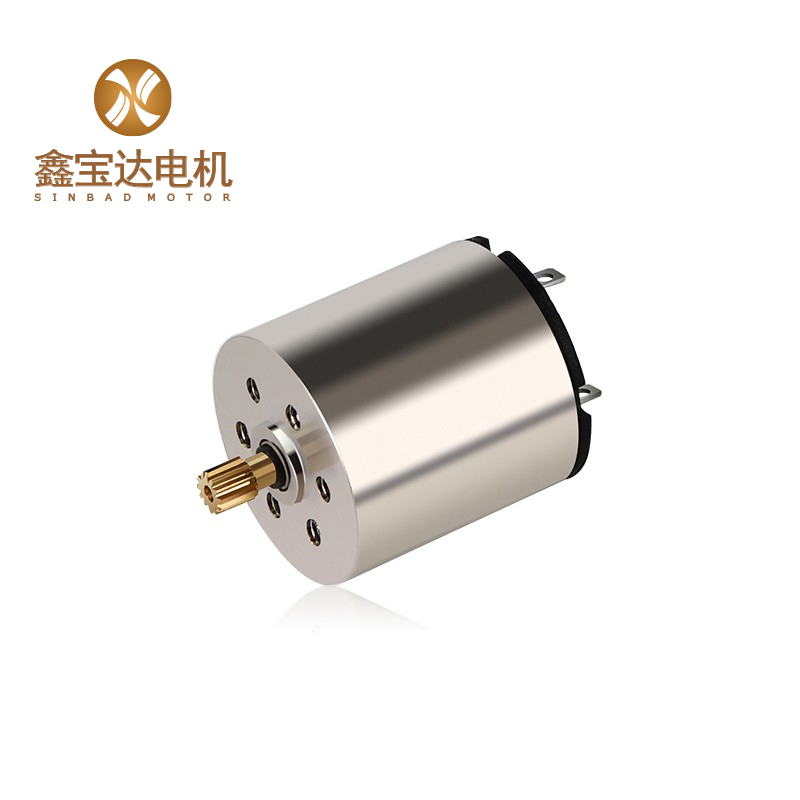

Medical equipment coreless brushed dc motor XBD-1722

Product Introduction

XBD-1722 precious metal brushed DC motor is a high-performance motor that utilizes precious metal brushes to provide excellent efficiency and performance. The motor operates smoothly and quietly while delivering high torque output and precise control, making it ideal for a wide range of applications. The motor features a compact and lightweight design, allowing for easy integration into various systems. With a long operational lifespan, this motor is highly reliable and durable. Additionally, the XBD-1722 motor is customizable to meet specific requirements, ensuring greater versatility and flexibility in any application. Integrated gearbox and encoder options are available to further customize motor performance to meet the needs of different industrial applications.

Application

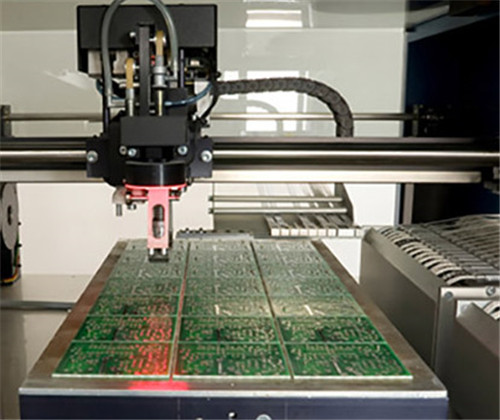

Sinbad coreless motor have a wide range of application such as robots, drones, medical equipment, automobiles, information and communications, power tools, beauty equipment, precision instruments and military industry.

Advantage

The advantages of the XBD-1722 Precious Metal Brushed DC Motor:

1. High efficiency: The motor uses precious metal brushes that provide superior conductivity, ensuring high efficiency and performance.

2. Smooth and quiet operation: The motor operates smoothly and quietly, making it ideal for applications where noise is a concern.

3. High torque output: The motor delivers high torque output, providing precise control and increased power to various systems.

4. Compact and lightweight design: The motor's compact and lightweight design allows for easy integration into various systems.

5. Long operational lifespan: The motor is highly reliable and durable, providing a long operational lifespan.

6. Customizable: The motor can be customized to meet specific application requirements, ensuring greater versatility and flexibility.

7. Gearbox and encoder options available: Integrated gearbox and encoder options are available to further customize motor performance to meet the needs of different industrial applications.

Parameter

| Motor model 1722 | |||||

| Brush material precious metal | |||||

| At nominal | |||||

| Nominal voltage | V |

3 |

6 |

12 |

24 |

| Nominal speed | rpm |

8800 |

10400 |

10400 |

10400 |

| Nominal current | A |

0.89 |

0.58 |

0.37 |

0.18 |

| Nominal torque | mNm |

2.12 |

2.42 |

2.95 |

2.96 |

|

Free load |

|||||

| No-load speed | rpm |

11000 |

13000 |

13000 |

13000 |

| No-load current | mA |

65 |

30 |

30 |

10 |

|

At max efficiency |

|||||

| Max efficiency | % |

76.7 |

80.4 |

75.4 |

79.6 |

| Speed | rpm |

0 |

11765 |

11505 |

11765 |

| Current | A |

0.0 |

0.3 |

0.2 |

0.1 |

| Torque | mNm |

0.0 |

1.1 |

1.7 |

1.4 |

|

At max output power |

|||||

| Max output power | W |

3.1 |

4.1 |

5.0 |

5.0 |

| Speed | rpm |

5500 |

6500 |

6500 |

6500 |

| Current | A |

2.1 |

1.4 |

0.9 |

0.4 |

| Torque | mNm |

5.3 |

6.0 |

7.4 |

7.4 |

|

At stall |

|||||

| Stall current | A |

4.2 |

2.8 |

1.7 |

0.9 |

| Stall torque | mNm |

10.6 |

12.1 |

14.74 |

14.8 |

|

Motor constants |

|||||

| Terminal resistance | Ω |

0.71 |

2.14 |

6.94 |

27.91 |

| Terminal inductance | mH |

0.23 |

0.68 |

0.23 |

0.73 |

| Torque constant | mNm/A |

2.56 |

4.36 |

8.66 |

17.42 |

| Speed constant | rpm/V |

3666.7 |

2166.7 |

1083.3 |

541.7 |

| Speed/Torque constant | rpm/mNm |

1037.5 |

1076.4 |

882.8 |

877.7 |

| Mechanical time constant | ms |

8.5 |

9.7 |

8.3 |

7.9 |

| Rotor inertia | g·cm² |

0.78 |

0.86 |

0.90 |

0.86 |

| Number of pole pairs 1 | |||||

| Number of phase 5 | |||||

| Weight of motor | g | 24 | |||

| Typical noise level | dB | ≤38 | |||

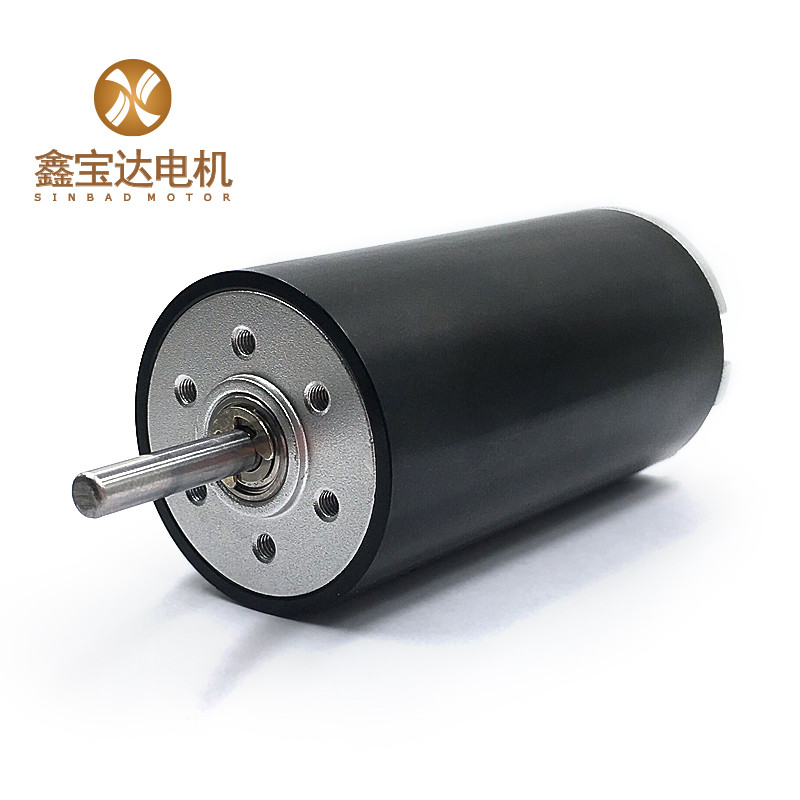

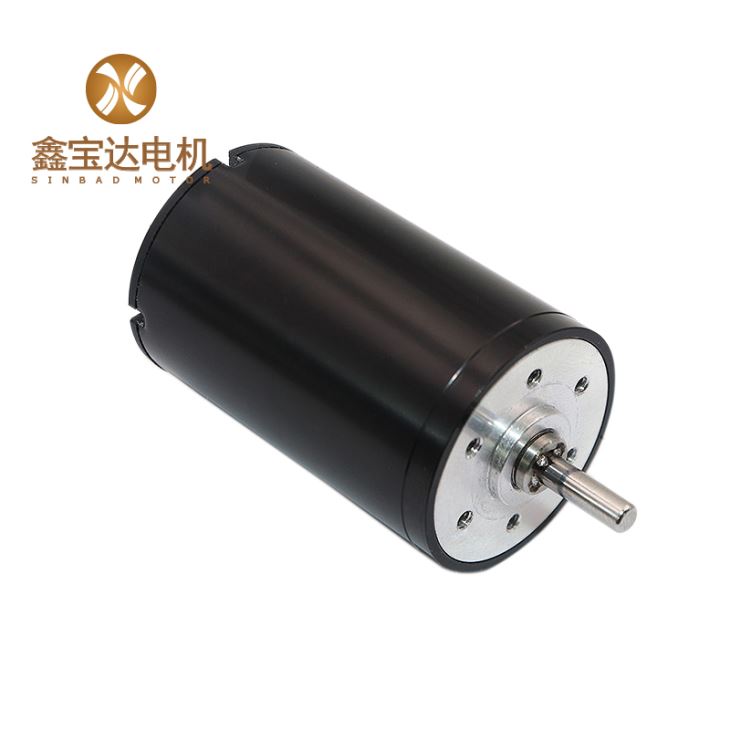

Samples

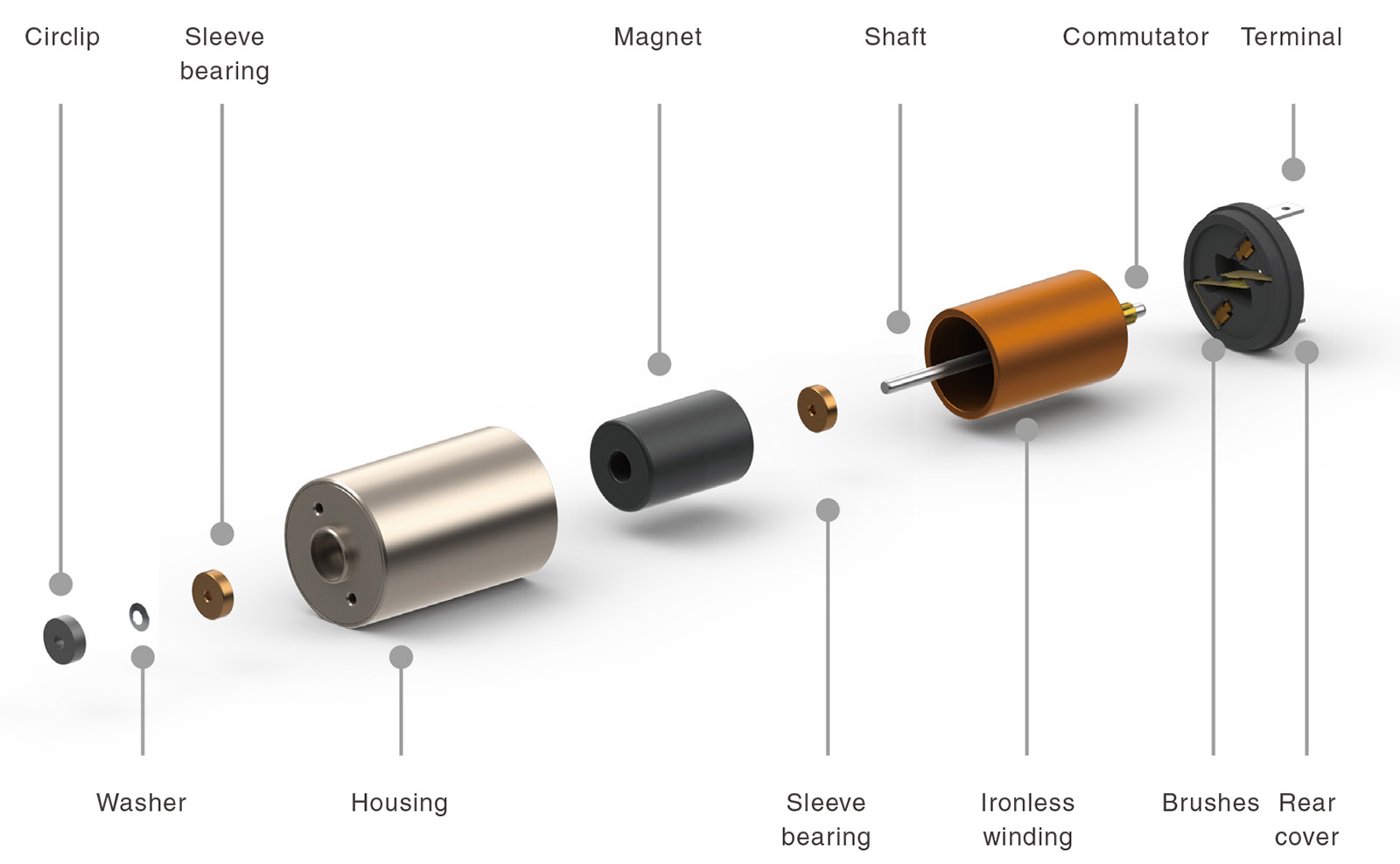

Structures

FAQ

A: Yes. We are a manufacturer specializing in Coreless DC Motor since 2011.

A: We have QC team comply with TQM, each step is in compliance to the standards.

A: Normally, MOQ=100pcs. But small batch 3-5 piece is accepted.

A: Sample is available for you. please contact us for details. Once we charge you sample fee, please feel easy, it will be refund when you place mass order.

A: send us inquiry → receive our quotation → negotiate details → confirm the sample → sign contract/deposit → mass production → cargo ready → balance/delivery → further cooperation.

A: Delivery time depends on the quantity you order. usually it takes 30~45 calendar days.

A: We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

A: We accept payment by T/T, PayPal, the other payment ways also could be accepted,Please contact us before you pay by the other payment ways. Also 30-50% deposit is available, the balance money should be paid before shipping.

How to Choose a Motor: A Guide to Finding the Perfect Motor for Your Needs

If you're like most people, you probably use your motor every day without even realizing it. Electric motors are found in everything from the electric motors that power cars to those in home appliances. But have you considered how to choose the right motor for your specific needs? In this article, we'll explore some of the key factors to keep in mind when choosing a motor so you can make an informed decision and get the best performance.

motor type

Before we dive into how to choose a motor, it's important to understand the different types available. There are a wide variety of motors on the market, from small motors found in toys and appliances to large industrial motors used in manufacturing processes. Here are some of the most common motor types you'll come across:

- DC Motors: These motors run on DC and are commonly found in toys, small electronics, and automotive applications.

- Alternating Current Motors: Alternating Current (AC) motors are used in a wide variety of applications, from home appliances to industrial machinery.

- Stepper Motors: These motors rotate in small, precise increments and are commonly used in automation, robotics, and 3D printing.

- Servo Motors: Servo motors are similar to stepper motors but offer a higher degree of precision and control. They are commonly used in robotics, industrial machinery and aerospace applications.

Now that we've covered the basic types of motors, let's explore how to choose the right one for your needs.

Factors to consider

The following factors should be kept in mind when selecting a motor:

- Power: One of the most important factors to consider when selecting a motor is power. You need to make sure the motor is powerful enough to provide the performance you need. Power is usually measured in watts or horsepower (HP).

- Speed: The speed of the motor is also an important factor to consider. Certain applications, such as manufacturing processes, require motors that can operate at high speeds, while others, such as robotics, benefit from motors that can operate at low speeds with high torque.

- Size: The size of the motor is also important as it affects the overall performance and efficiency of the system. Make sure you choose the right motor size for your application.

- Voltage: The voltage of the motor is another important consideration. Make sure the motor is compatible with the mains voltage you plan to use.

- Environment: The environment in which the motor will be used also plays a role in the selection process. Motors used in harsh environments, such as those with extreme temperatures or high levels of dust or humidity, need to be designed to withstand these conditions.

- Cost: In the end, cost is always a consideration. Make sure the motor you choose fits your budget, but don't sacrifice quality to save a few bucks.

in conclusion

In conclusion, understanding how to select the right motor for your needs requires careful consideration of various factors including power, speed, size, voltage, environment and cost. By keeping these factors in mind, you can choose a motor that will provide the performance and reliability required for your particular application. Whether you're looking for a small motor for a toy or appliance or a large industrial motor for a manufacturing process, taking the time to select the right motor can make your project a success.