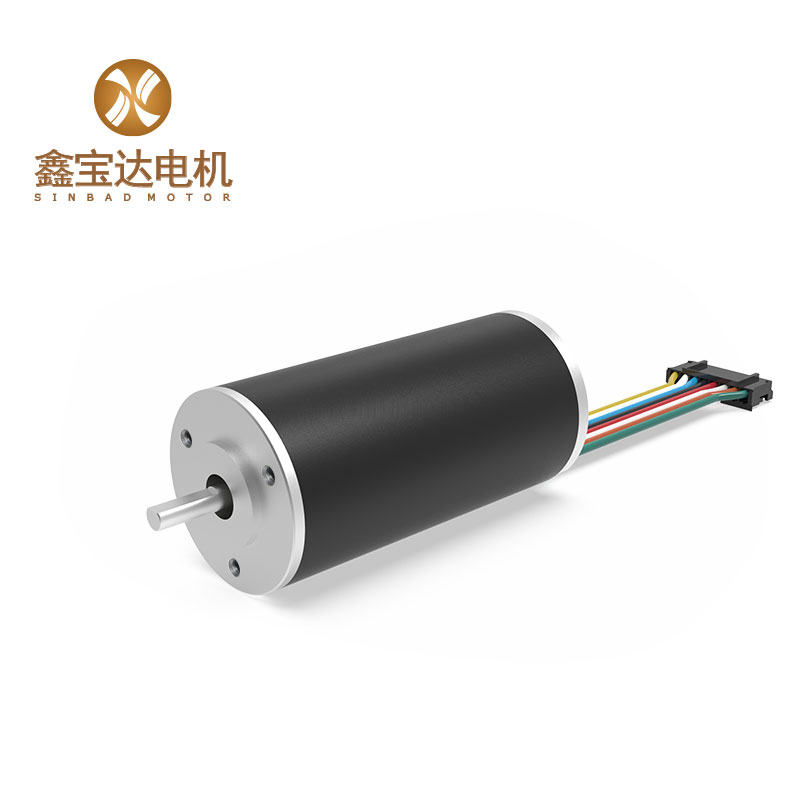

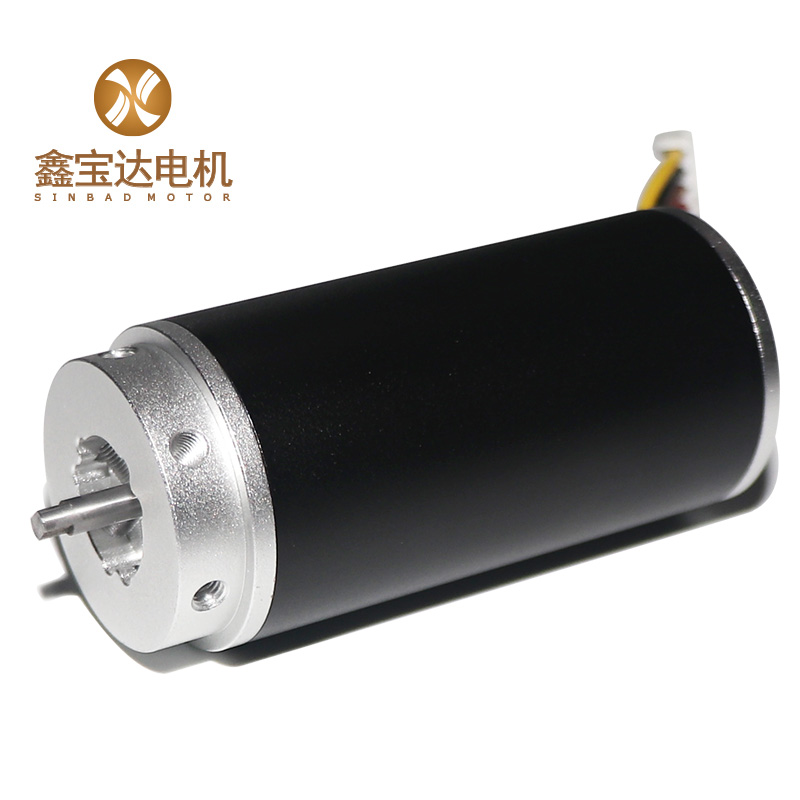

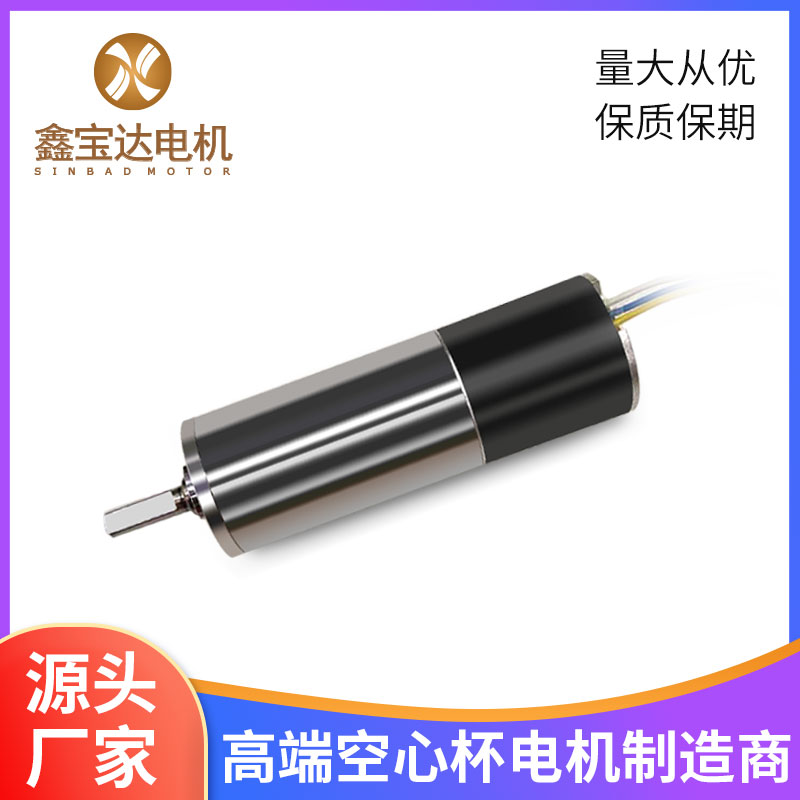

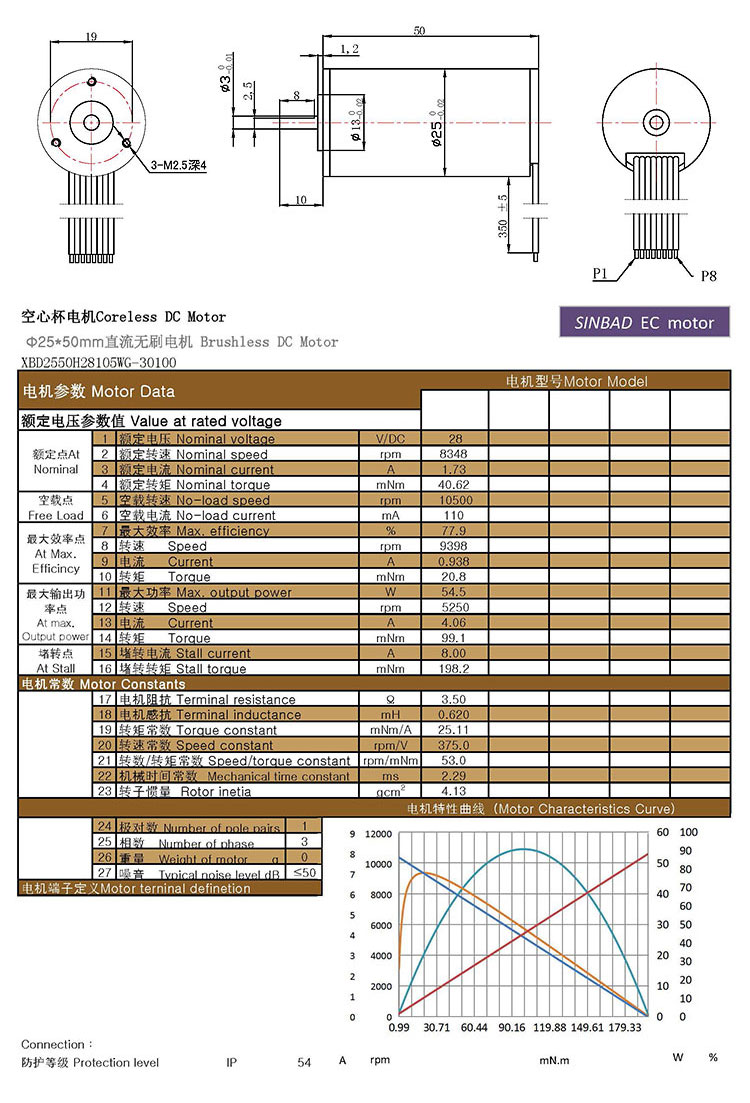

XBD-2550 brushless motor controller coreless motor 12v dc motor design

Product Introduction

In practical applications, brushless DC motors are widely used in various fields. In the automotive industry, our XBD-2550 brushless DC motors are used in the drive systems of electric vehicles. Their efficient and reliable performance enable electric vehicles to achieve longer cruising range and faster acceleration. In the field of home appliances, XBD-2550 brushless DC motors are used in various home appliances, such as washing machines, vacuum cleaners, etc. Their low noise and high efficiency make home appliances more energy-saving and environmentally friendly. In addition, brushless DC motors are also widely used in industrial automation, aerospace, drones and other fields.

In general, brushless DC motors have become an important part of the modern electrification field with their advantages such as high efficiency, low noise, long life, and precise control. Their wide application in various fields will further promote brushless DC motor technology. development and innovation.

Advantage

Advantages of the XBD-2550 Coreless Brushless DC Motor include:

1.Precise control: Brushless motors can achieve precise speed and position control through precise electronic control.

2.No sparks: Brushless motors have no brushes, so they do not produce sparks and are suitable for use in flammable and explosive environments.

3.Good high-temperature characteristics: The material and structure of our XBD-2550 brushless motor give it better performance in high-temperature environments.

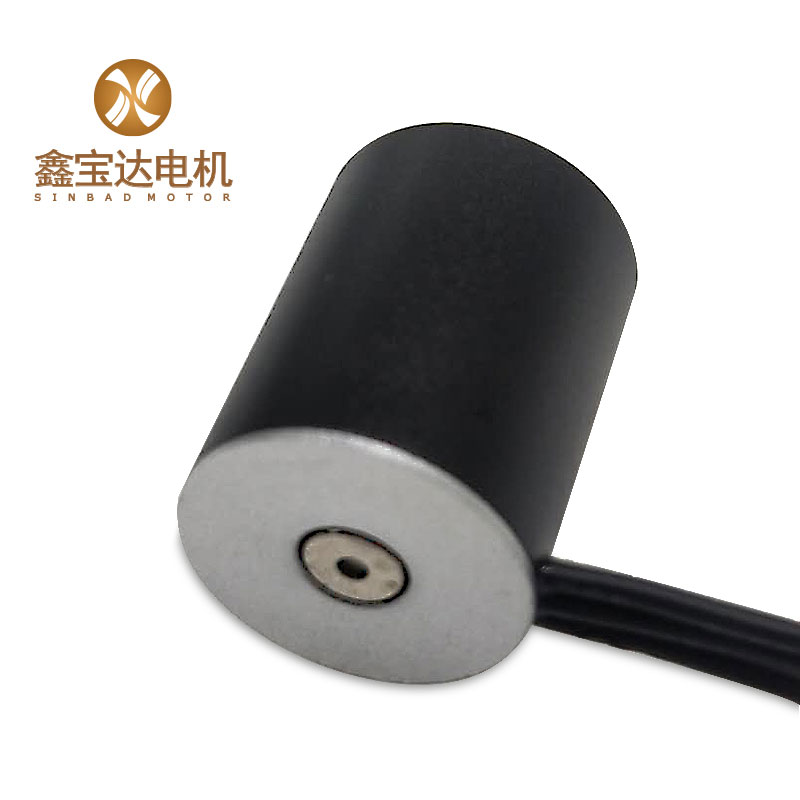

4.Lightweight: Brushless motors are usually lighter than brushed motors and are suitable for occasions with higher weight requirements.

5.High power density: Brushless motors can provide greater power output in a smaller size.

6.High dynamic response: The electronic commutation of the brushless motor makes it have faster dynamic response capability.

7.Environmental protection: Brushless motors do not need to use harmful brush materials and are more environmentally friendly.

8.Strong adaptability: The XBD-2550 Brushless motors can adapt to different working environments and work requirements, and have strong versatility.

Application

Sinbad coreless motor have a wide range of application such as robots, drones, medical equipment, automobiles, information and communications, power tools, beauty equipment, precision instruments and military industry.

Parameter

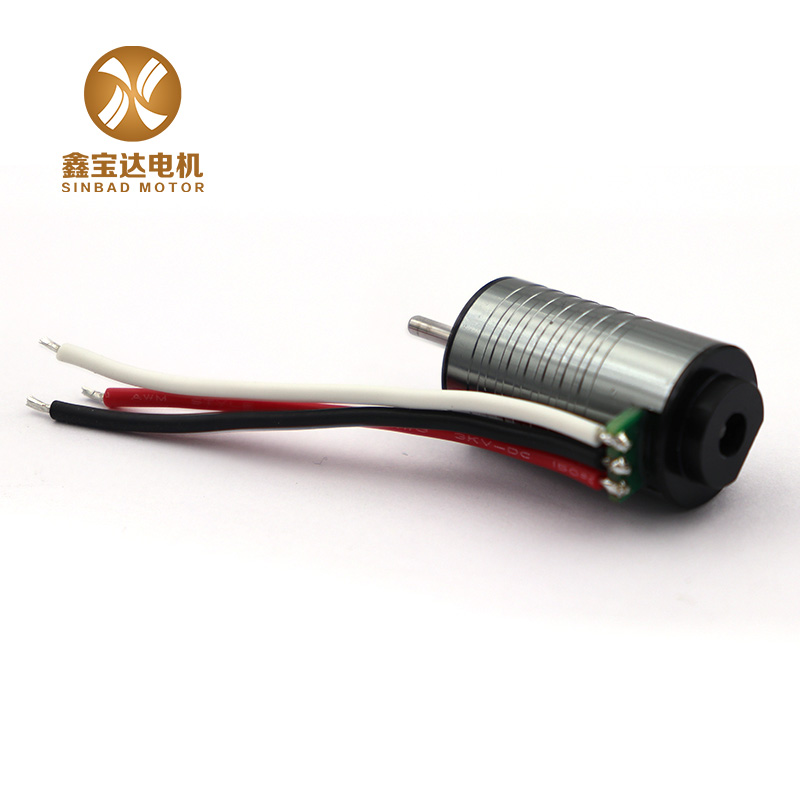

Samples

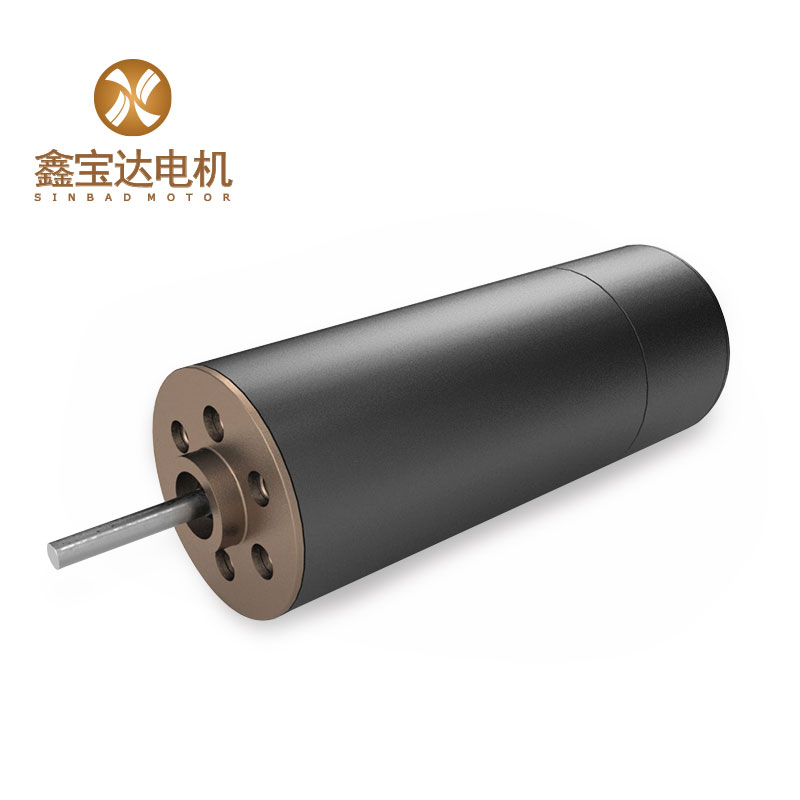

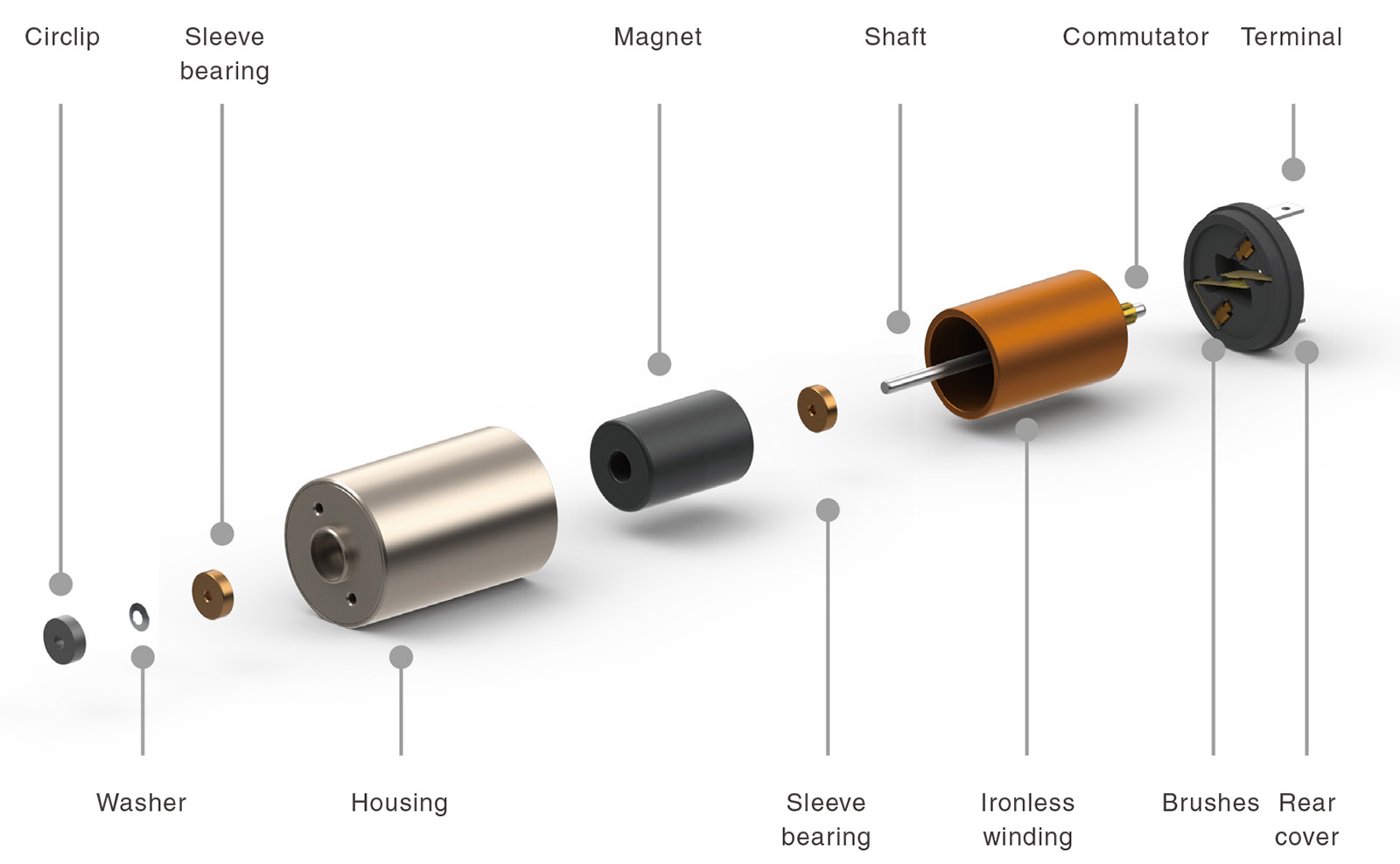

Structures

FAQ

A: Yes. We are a manufacturer specializing in Coreless DC Motor since 2011.

A: We have QC team comply with TQM, each step is in compliance to the standards.

A: Normally, MOQ=100pcs. But small batch 3-5 piece is accepted.

A: Sample is available for you. please contact us for details. Once we charge you sample fee, please feel easy, it will be refund when you place mass order.

A: send us inquiry → receive our quotation → negotiate details → confirm the sample → sign contract/deposit → mass production → cargo ready → balance/delivery → further cooperation.

A: Delivery time depends on the quantity you order. usually it takes 15-25 working days.

A: We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

A: We accept payment by T/T, PayPal, the other payment ways also could be accepted,Please contact us before you pay by the other payment ways. Also 30-50% deposit is available, the balance money should be paid before shipping.

Coreless brushless DC motors offer several advantages over traditional DC motors. Some of these advantages are:

1. Efficient

Coreless brushless DC motors are efficient machines because they are brushless. This means they do not rely on brushes for mechanical commutation, reducing friction and eliminating the need for frequent maintenance. This efficiency makes coreless brushless DC motors ideal for a variety of applications requiring high performance and low energy consumption.

2. Compact design

Coreless BLDC motors are compact and ideal for a variety of applications, including those requiring small, lightweight motors. The lightweight nature of the motors makes them ideal for applications involving weight-sensitive equipment. This compact design is a key feature making it suitable for industries such as aerospace, medical and robotics.

3. Low noise operation

Coreless brushless DC motors are designed to run with minimal noise. Because the motor does not use brushes for commutation, it produces less mechanical noise than conventional motors. The quiet operation of the motor makes it an excellent choice for a range of applications. Additionally, Coreless BLDC motors can run at very high speeds without producing excessive noise, making them ideal for high-speed applications.

4. High precision control

Coreless BLDC motors provide excellent speed and torque control, making them an excellent choice for applications requiring high precision performance. This precise control is achieved through the use of a closed-loop control system that provides feedback to the motor controller, enabling it to adjust speed and torque according to application needs.

5. Long life

Compared with traditional DC motors, coreless brushless DC motors have a longer service life. The absence of brushes in a coreless brushless DC motor minimizes the wear and tear associated with brush commutation. In addition, coreless brushless DC motors rely on a closed-loop control system and are less prone to failure than traditional DC motors. This extended service life makes coreless brushless DC motors an excellent choice for high reliability applications.

In conclusion

Coreless BLDC motors offer excellent advantages and advantages over traditional DC motors. These advantages include high efficiency, compact design, quiet operation, high precision control and long service life. With the advantages of coreless brushless DC motors, they are ideal for a variety of applications in different industries, including robotics, aerospace, medical devices, and automation, among others.