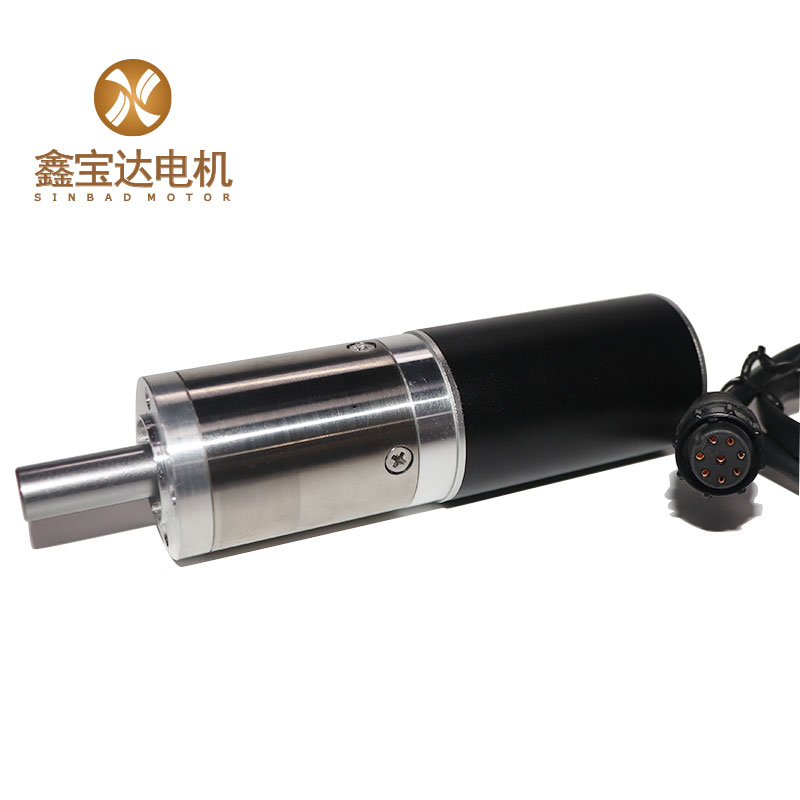

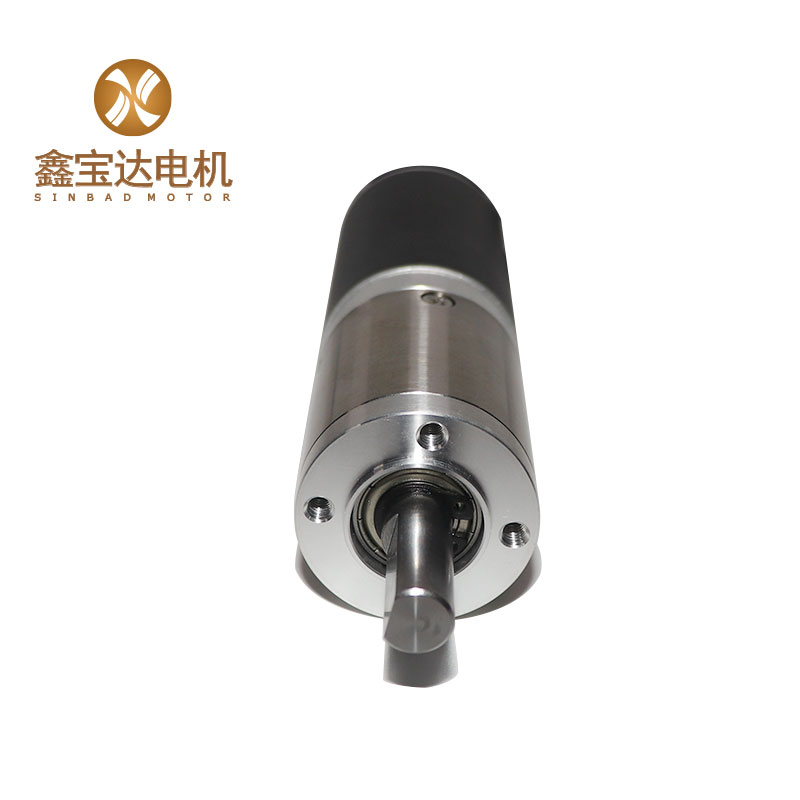

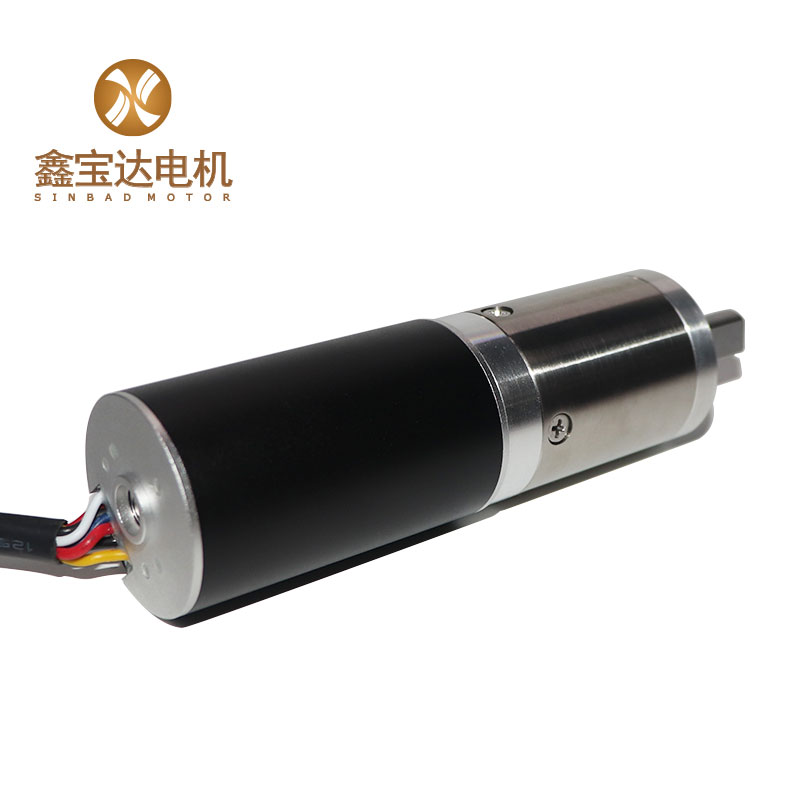

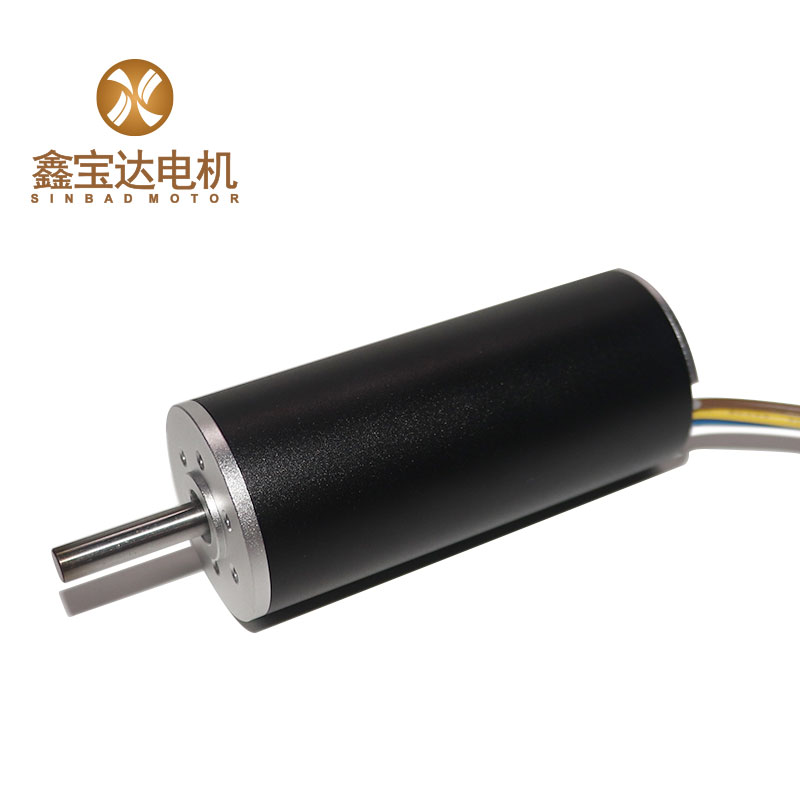

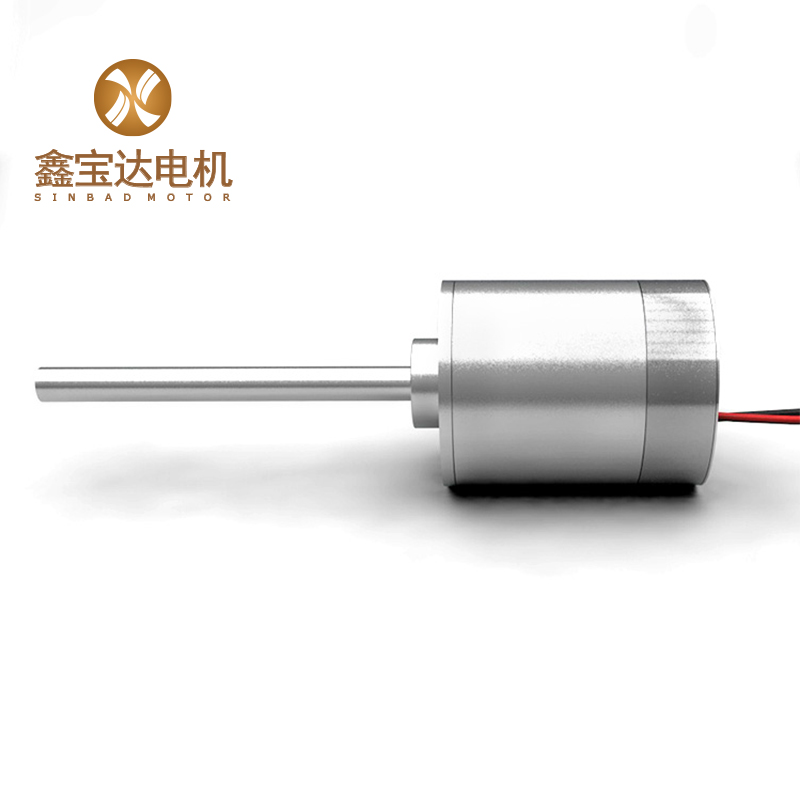

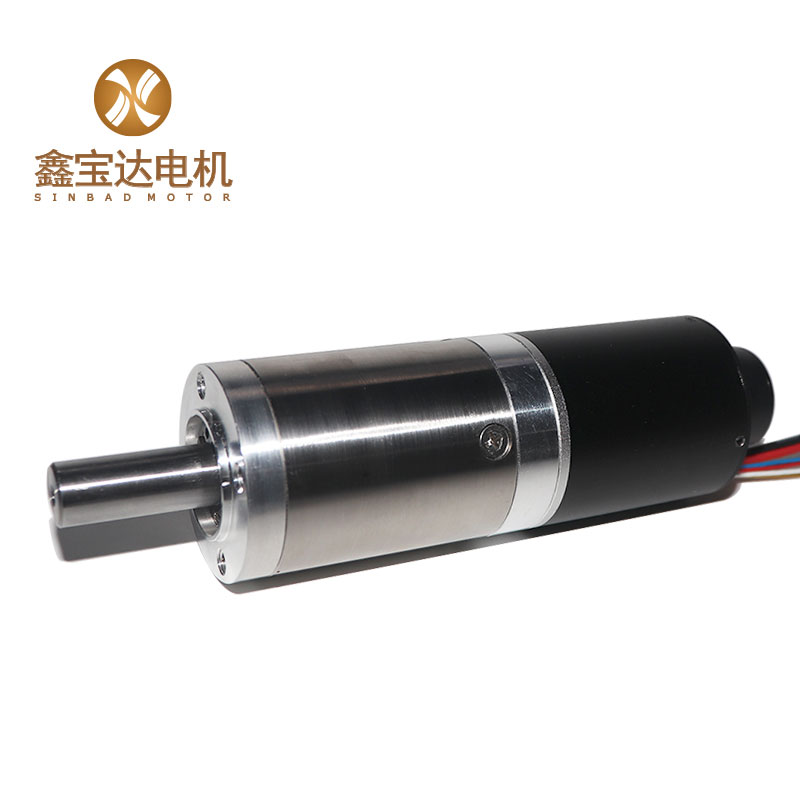

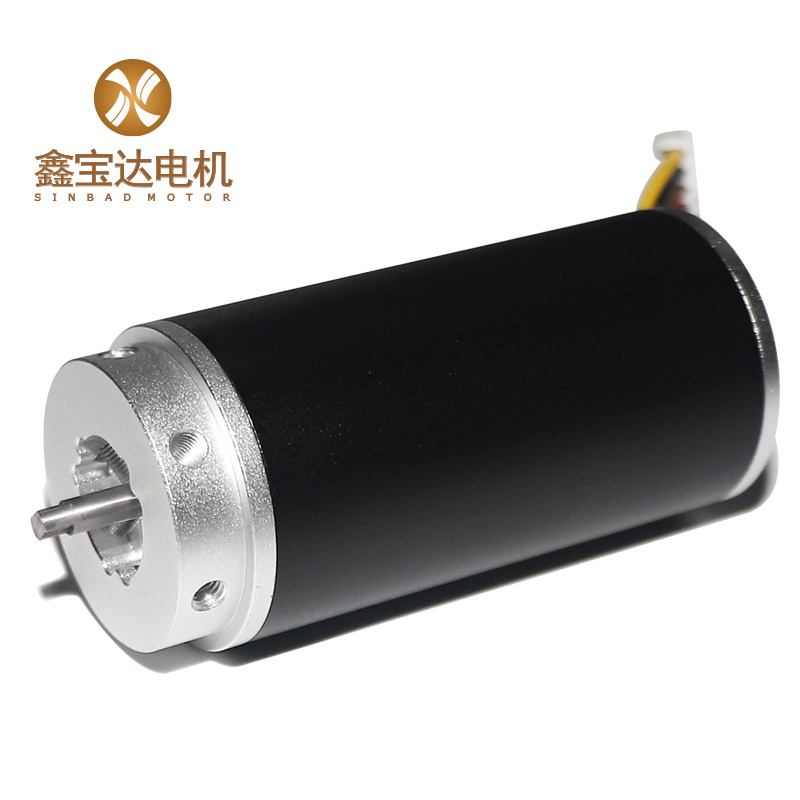

XBD-3660 BLDC gearbox servo motor controller design using matlab applications treadmill motor projects

Product Introduction

The XBD-3660 Coreless Brushless DC Motor is a high-performance motor that can be customized to meet the specific requirements of customers. Its coreless construction and brushless design provide smooth operation, reduce cogging, and increase longevity. This motor can be adjusted to operate at various speeds and power outputs to meet the demands of a wide range of applications. Additionally, customers can modify the parameters of the motor to meet their individual requirements and specifications. Overall, the XBD-3660 Coreless Brushless DC Motor is a versatile and reliable motor that can be tailored to meet the specific requirements of your application. Our custom precision brushless DC motors are designed to provide optimal power solutions for high-end applications. Each motor is tailor-made according to the customer’s specific requirements, providing comprehensive customization services from motor size and shape to electrical parameters. The motor uses the latest brushless technology and a precision bearing system to ensure high performance and long life in a variety of applications.

Application

Sinbad coreless motor have a wide range of application such as robots, drones, medical equipment, automobiles, information and communications, power tools, beauty equipment, precision instruments and military industry.

Advantage

Advantages of XBD-3660 Coreless Brushless DC Motor:

1. Coreless construction and brushless design provide smooth operation and longevity.

2. Reduced cogging improves overall performance.

3. Motor speed and power output can be customized to meet specific application requirements.

4. Durable design ensures reliable performance even in harsh environments.

5. Custom parameter options available to meet individual customer specifications.

Customizable parameters can be customized based on specific customer requirements, including voltage range, Speed range, power output, shaft diameter, motor length,etc.

Parameter

| Motor model 3660 | ||||

| At nominal | ||||

| Nominal voltage | V |

12 |

24 |

36 |

| Nominal speed | rpm |

4463 |

4930 |

5100 |

| Nominal current | A |

3.24 |

1.93 |

1.30 |

| Nominal torque | mNm |

64.12 |

69.36 |

66.71 |

|

Free load |

||||

| No-load speed | rpm |

5250 |

5800 |

6000 |

| No-load current | mA |

260 |

150 |

120 |

|

At max efficiency |

||||

| Max efficiency | % |

78.5 |

78.9 |

77.0 |

| Speed | rpm |

4725 |

5220 |

5340 |

| Current | A |

2.244 |

1.335 |

0.987 |

| Torque | mNm |

42.70 |

46.24 |

48.92 |

|

At max output power |

||||

| Max output power | W |

58.8 |

70.2 |

69.9 |

| Speed | rpm |

2625 |

2900 |

3000 |

| Current | A |

10.2 |

6.1 |

4.1 |

| Torque | mNm |

213.70 |

231.20 |

222.36 |

|

At stall |

||||

| Stall current | A |

20.10 |

12.00 |

8.00 |

| Stall torque | mNm |

427.40 |

462.39 |

444.72 |

|

Motor constants |

||||

| Terminal resistance | Ω |

0.60 |

2.00 |

4.50 |

| Terminal inductance | mH |

0.260 |

0.945 |

2.055 |

| Torque constant | mNm/A |

21.54 |

39.02 |

56.44 |

| Speed constant | rpm/V |

437.5 |

241.7 |

166.7 |

| Speed/Torque constant | rpm/mNm |

12.3 |

12.5 |

13.5 |

| Mechanical time constant | ms |

4.44 |

4.54 |

4.88 |

| Rotor inertia | g·cm² |

34.53 |

34.53 |

34.53 |

| Number of pole pairs 1 | ||||

| Number of phase 3 | ||||

| Weight of motor | g | 269 | ||

| Typical noise level | dB | ≤45 | ||

Samples

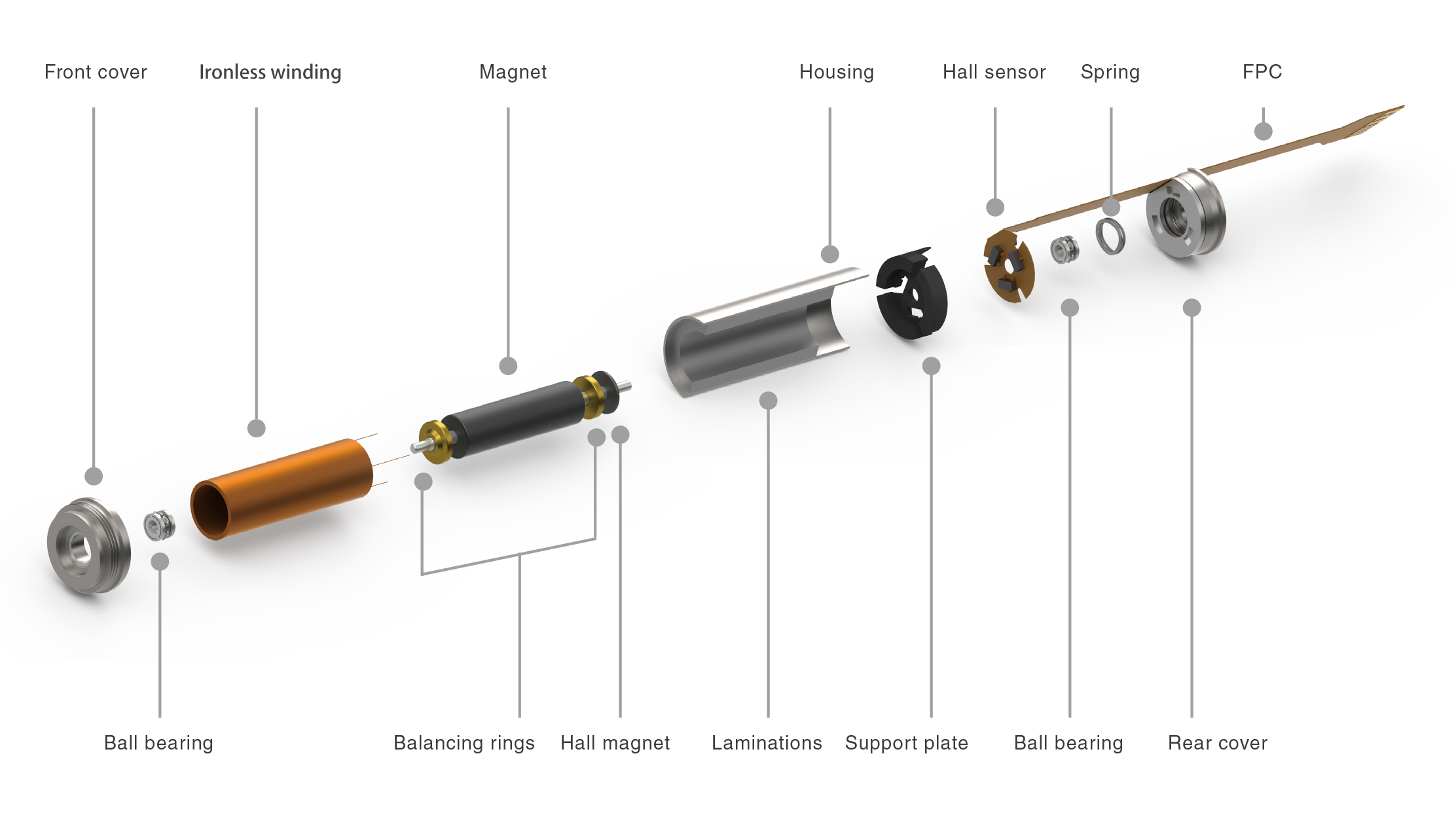

Structures

FAQ

A: Yes. We are a manufacturer specializing in Coreless DC Motor since 2011.

A: We have QC team comply with TQM, each step is in compliance to the standards.

A: Normally, MOQ=100pcs. But small batch 3-5 piece is accepted.

A: Sample is available for you. please contact us for details. Once we charge you sample fee, please feel easy, it will be refund when you place mass order.

A: send us inquiry → receive our quotation → negotiate details → confirm the sample → sign contract/deposit → mass production → cargo ready → balance/delivery → further cooperation.

A: Delivery time depends on the quantity you order. usually it takes 30~45 calendar days.

A: We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

A: We accept payment by T/T, PayPal, the other payment ways also could be accepted,Please contact us before you pay by the other payment ways. Also 30-50% deposit is available, the balance money should be paid before shipping.

Coreless Brushless DC Motors: Pros and Benefits

Coreless brushless DC motors play an important role in modern robotics and automation. They are very advanced machines with many advantages and advantages over conventional motors including high efficiency, compact design, light weight and quiet operation.

In this article, we will discuss in detail the advantages and benefits of coreless brushless DC motors over traditional motors.

What is a Coreless Brushless DC Motor?

A Coreless Brushless DC Motor is a highly advanced machine that operates on electromagnetic principles. These motors are typically used in high-speed applications such as robotics, automation, and medical equipment.

An ironless BLDC motor differs from a traditional DC motor in that it has no iron core inside the rotor. Instead, the motor's rotor consists of copper wire wrapped around coils that provide a magnetic field and generate torque.