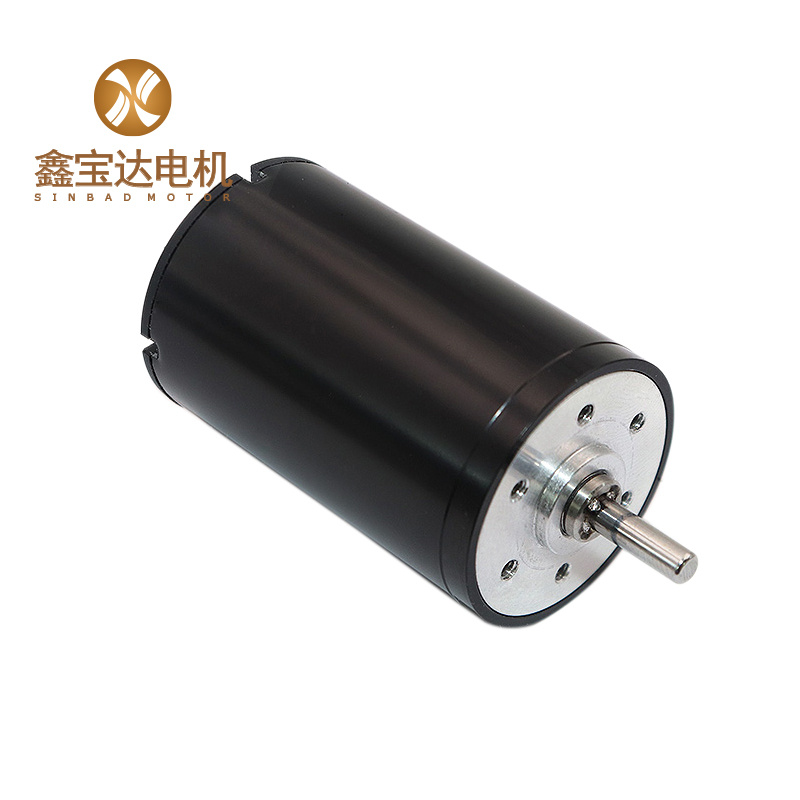

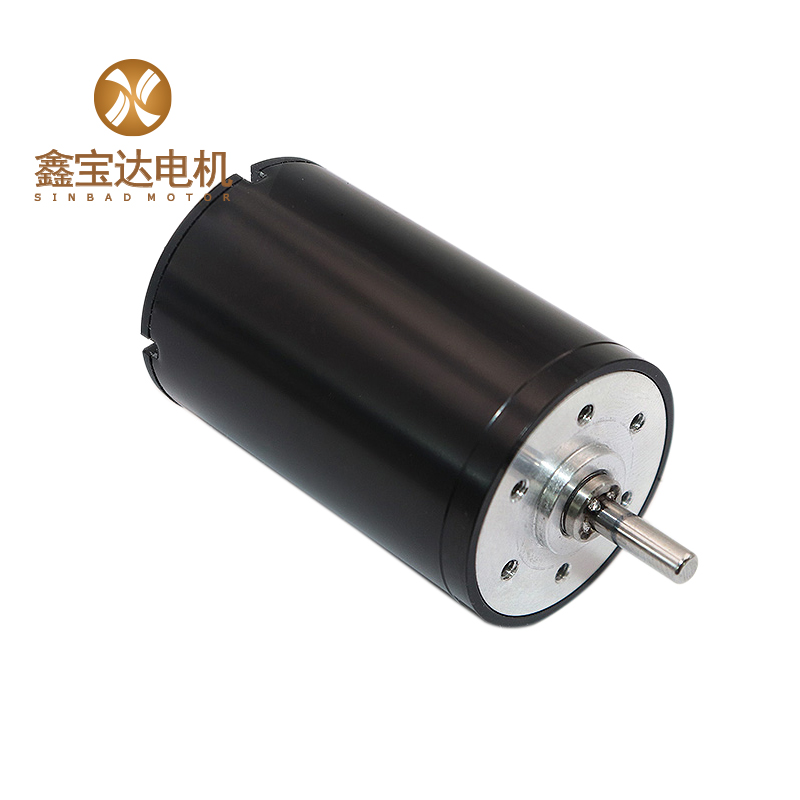

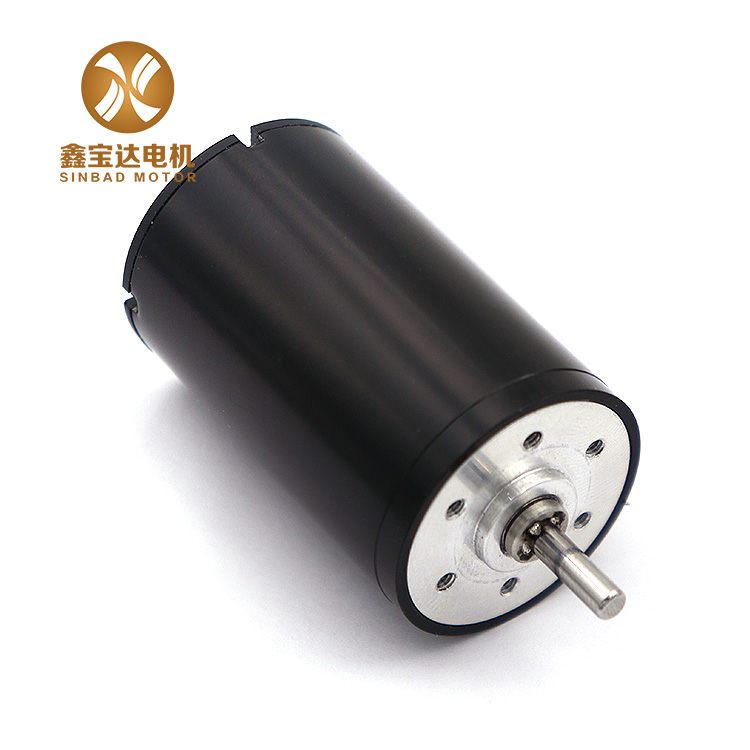

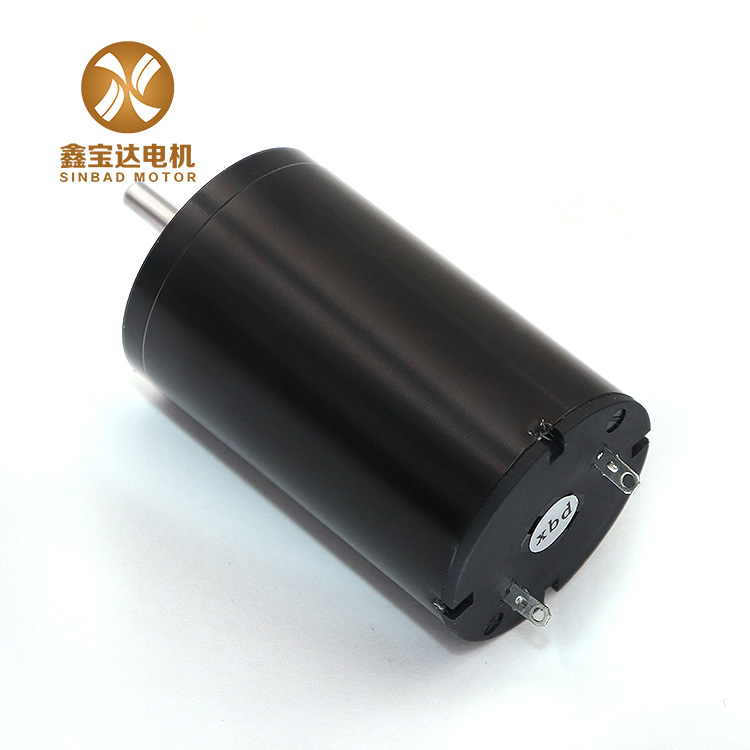

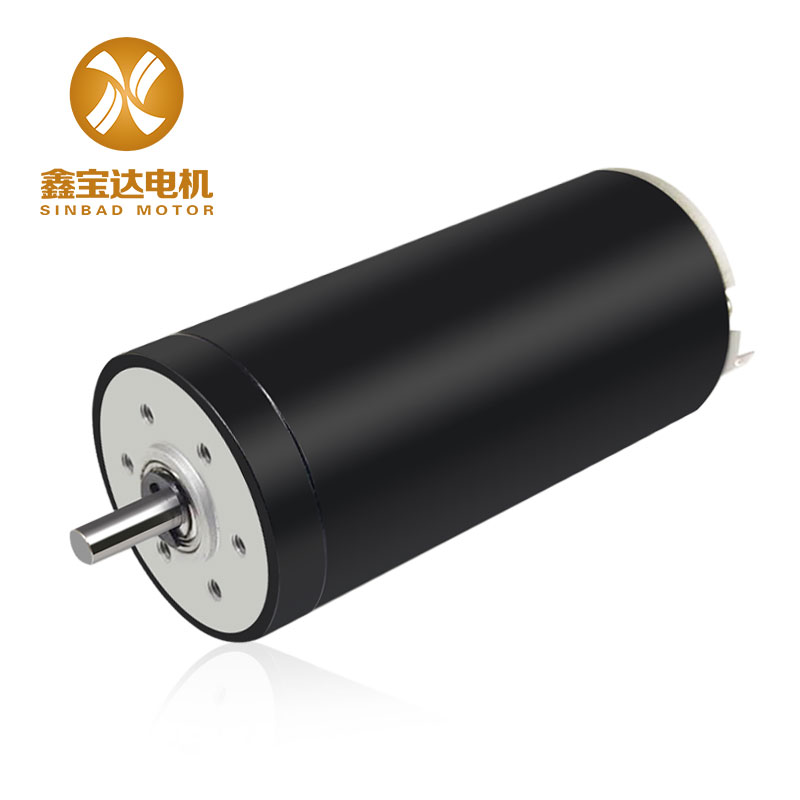

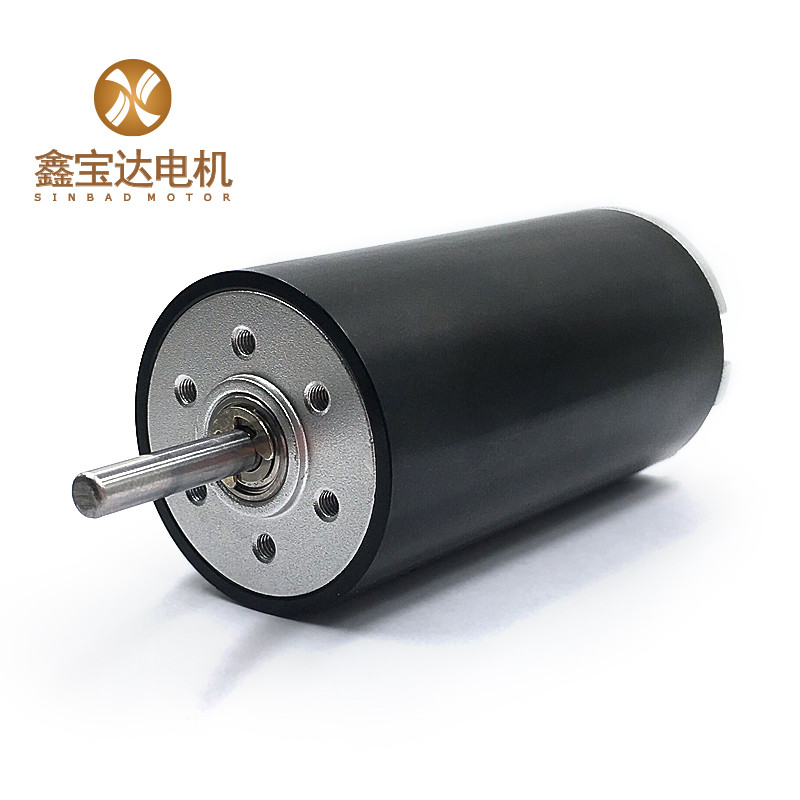

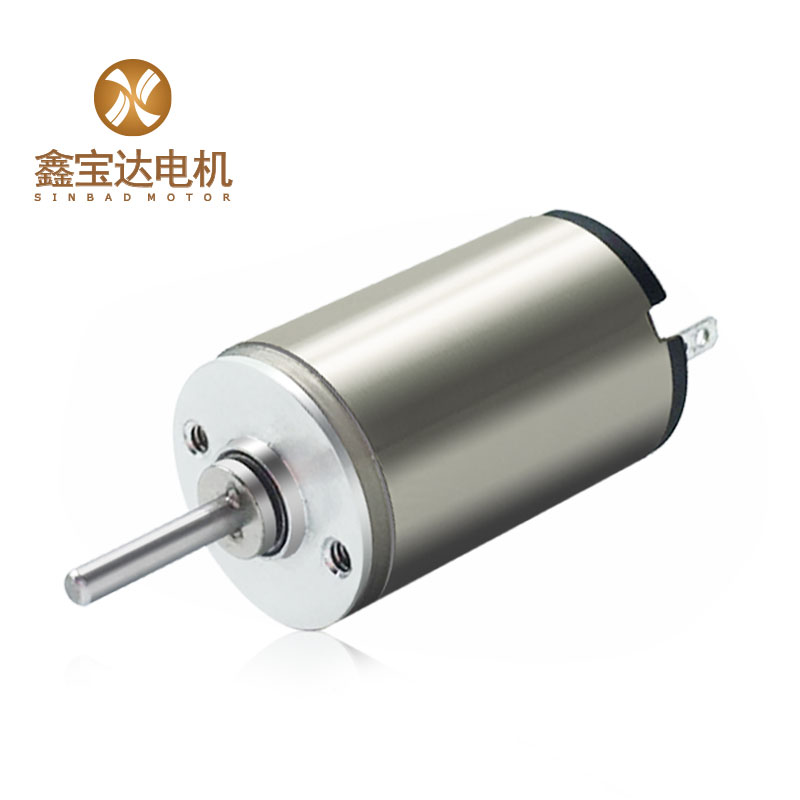

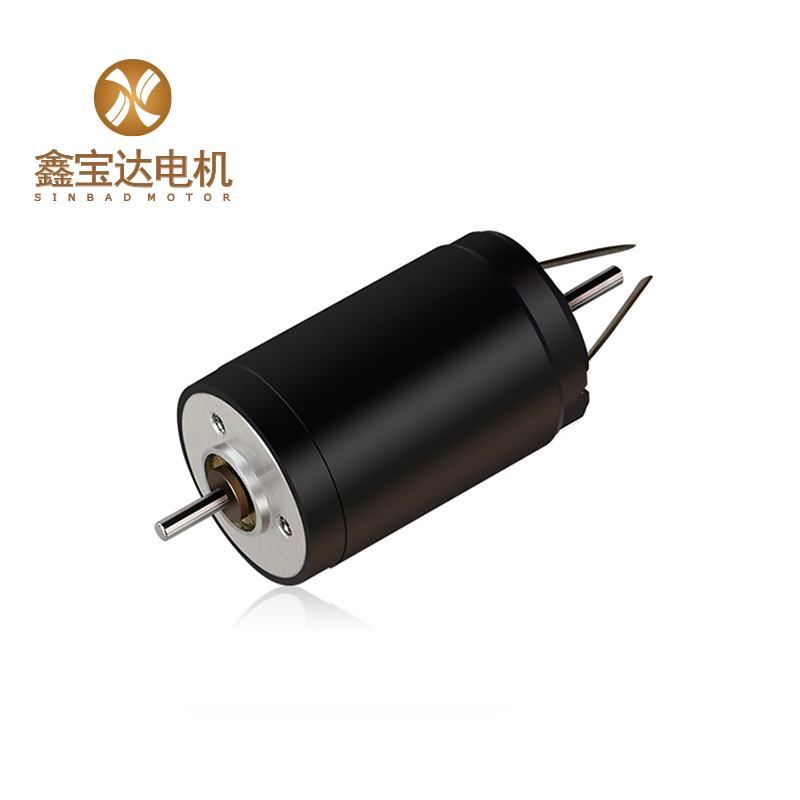

XBD-2642 Precious Metal Brushed DC Motor

Product Introduction

The XBD-2642 Precious Metal Brushed DC Motor is a high-performance and reliable motor that is ideal for a wide range of applications. The motor features superior conductivity and precious metal brushes that result in efficient and reliable performance. With high torque output, the motor provides precise control and increased power for demanding applications. The motor operates smoothly and quietly, making it suitable for noise-sensitive environments. The compact and lightweight design of the motor allows for easy integration into various systems. The motor has a long operational lifespan, ensuring durability and reliability. Moreover, the motor can also be customized to meet specific application requirements. The XBD-2642 motor also offers integrated gearbox and encoder options for enhanced motor performance.

Application

Sinbad coreless motor have a wide range of application such as robots, drones, medical equipment, automobiles, information and communications, power tools, beauty equipment, precision instruments and military industry.

Advantage

The advantages of XBD-2642 Precious Metal Brushed DC Motor are as follows:

1. High performance and reliability.

2. Excellent electrical conductivity and precious metal brushes, ensuring high efficiency and reliability.

3. High torque output, providing precise control and power increase functionality.

4. Smooth operation, low noise, suitable for noise-sensitive environments.

5. Compact and lightweight design, easy to integrate into various systems.

6. Long service life, ensuring durability and reliability.

7. Customizable according to specific application requirements.

8. Provides options for integrated gearboxes and encoders to enhance motor performance.

Parameter

| Motor model 2642 | |||||

| Brush material precious metal | |||||

| At nominal | |||||

| Nominal voltage | V |

6 |

9 |

12 |

24 |

| Nominal speed | rpm |

4895 |

7476 |

7452 |

7700 |

| Nominal current | A |

0.44 |

0.64 |

0.43 |

0.39 |

| Nominal torque | mNm |

4.01 |

5.97 |

5.44 |

9.25 |

|

Free load |

|||||

| No-load speed | rpm |

5500 |

8400 |

8100 |

8800 |

| No-load current | mA |

50 |

50 |

45 |

30 |

|

At max efficiency |

|||||

| Max efficiency | % |

77.8 |

81.7 |

81.7 |

80.7 |

| Speed | rpm |

5033 |

7686 |

7412 |

8008 |

| Current | A |

0.352 |

0.505 |

0.458 |

0.288 |

| Torque | mNm |

3.1 |

4.6 |

5.8 |

6.7 |

|

At max output power |

|||||

| Max output power | W |

5.3 |

11.9 |

14.4 |

17.0 |

| Speed | rpm |

2750 |

4200 |

4050 |

4400 |

| Current | A |

1.8 |

2.7 |

2.5 |

1.5 |

| Torque | mNm |

18.2 |

27.1 |

34.0 |

37.0 |

|

At stall |

|||||

| Stall current | A |

3.60 |

5.40 |

4.90 |

2.90 |

| Stall torque | mNm |

36.5 |

54.2 |

68.1 |

74.0 |

|

Motor constants |

|||||

| Terminal resistance | Ω |

1.67 |

1.67 |

2.45 |

8.28 |

| Terminal inductance | mH |

0.062 |

0.070 |

0.160 |

0.290 |

| Torque constant | mNm/A |

10.27 |

10.14 |

14.02 |

25.77 |

| Speed constant | rpm/V |

916.7 |

933.3 |

675.0 |

366.7 |

| Speed/Torque constant | rpm/mNm |

150.8 |

154.9 |

119.0 |

119.0 |

| Mechanical time constant | ms |

9.11 |

7.68 |

5.90 |

5.79 |

| Rotor inertia | g·cm² |

5.77 |

4.73 |

4.73 |

4.65 |

| Number of pole pairs 1 | |||||

| Number of phase 7 | |||||

| Weight of motor | g | 105 | |||

| Typical noise level | dB | ≤40 | |||

Samples

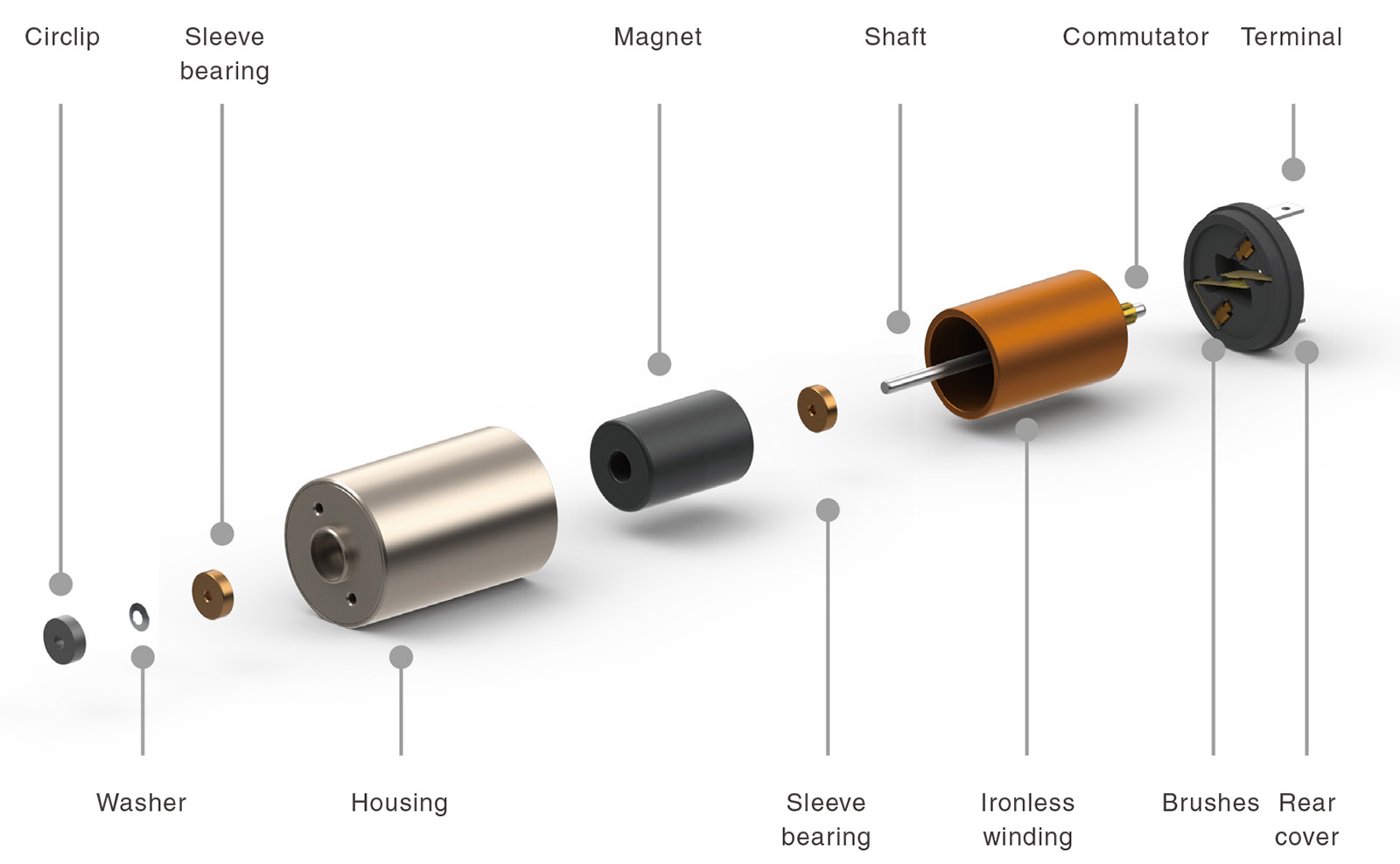

Structures

FAQ

A: Yes. We are a manufacturer specializing in Coreless DC Motor since 2011.

A: We have QC team comply with TQM, each step is in compliance to the standards.

A: Normally, MOQ=100pcs. But small batch 3-5 piece is accepted.

A: Sample is available for you. please contact us for details. Once we charge you sample fee, please feel easy, it will be refund when you place mass order.

A: send us inquiry → receive our quotation → negotiate details → confirm the sample → sign contract/deposit → mass production → cargo ready → balance/delivery → further cooperation.

A: Delivery time depends on the quantity you order. usually it takes 30~45 calendar days.

A: We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

A: We accept payment by T/T, PayPal, the other payment ways also could be accepted,Please contact us before you pay by the other payment ways. Also 30-50% deposit is available, the balance money should be paid before shipping.

High quality performance

Coreless brushed DC motors perform very well. The motor runs smoothly, with low noise and vibration. In addition, the high torque output of the motor ensures high-quality performance, making it ideal for precision applications in robotics, automation, medical equipment, and aerospace.

Long life

The coreless brushed DC motor has a long service life. The motor is designed to run for a long time without wearing out quickly. Additionally, the low heat generation of the motor extends the life of the motor, making it ideal for critical applications that require years of continuous operation.

In conclusion

Coreless brushed DC motors are an excellent solution for high-performance applications requiring precise motion, low inertia, high power-to-weight ratio, and efficient operation. With their compact size, lightweight design and low heat generation, coreless brushed DC motors revolutionized the motor industry.

So if you're looking for a reliable, efficient and high-performance motor, consider using a coreless brushed DC motor for your application.